The Ultimate Guide to Jack-up Systems

June 12, 2023

0

With their incredible capabilities, jack-up systems have transformed heavy construction projects. From bridge construction to mining and shipbuilding, these hydraulic systems excel at lifting and lowering heavy loads with precision.

Read on to discover the benefits of Jack-up Systems, hear from satisfied users, view our video, and explore applications in our image gallery.

Jump to a section:

• When are Jack-up Systems Used?

• Jack-up System Overview

• Video

• User Comments

• Project Gallery

• Jack-up Systems Compared

• Summary

When are Jack-up Systems Used?

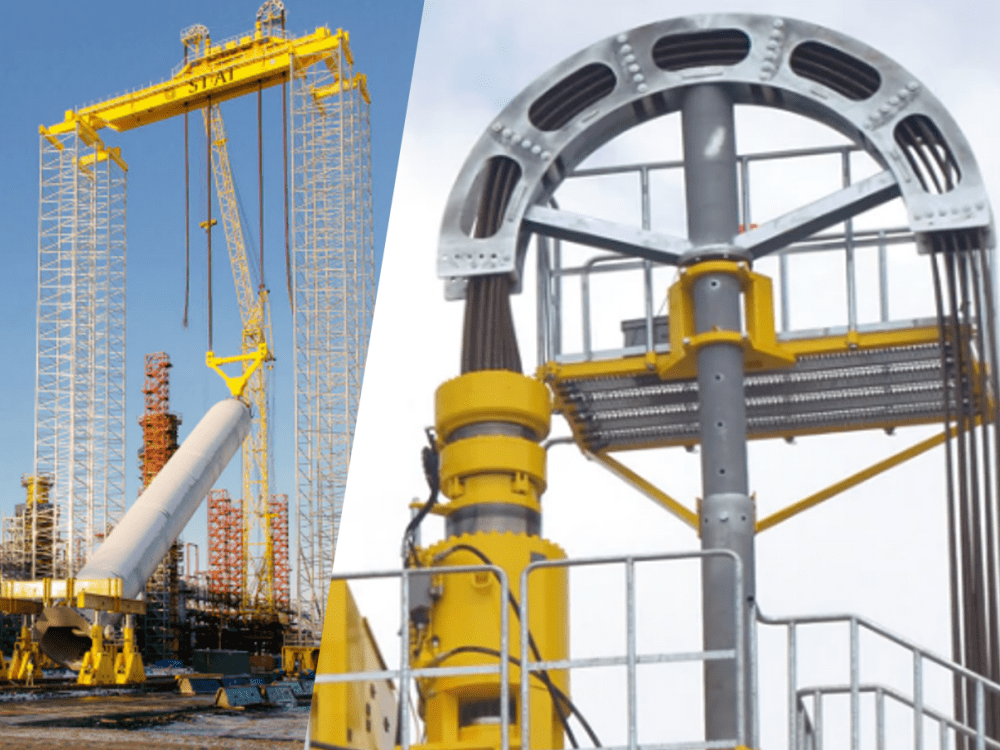

Enerpac Jack-up Systems are used extensively in construction projects – especially for bridges, for example whenever a deck section needs lifting or lowering. They can also be used in other industries too, such as mining, shipbuilding, dockyards, and decommissioning. The type of projects best suited to jack-up systems are those requiring the following:

• Multi-point lifting and lowering

• Ability to lift large and heavy loads weighing up to 3,360 tons (30,000 kN)

• Quick and easy mobilization

• Synchronized lifting and travel

• A system that fits where space or access is restricted

• When lifting the load from below (with header beams)

• When lifting the load from above (less often, and using slings)

• When the load has a large footprint

• When both speed and high accuracy are needed

• When it is important to lock the load mechanically

Jack-up System Overview

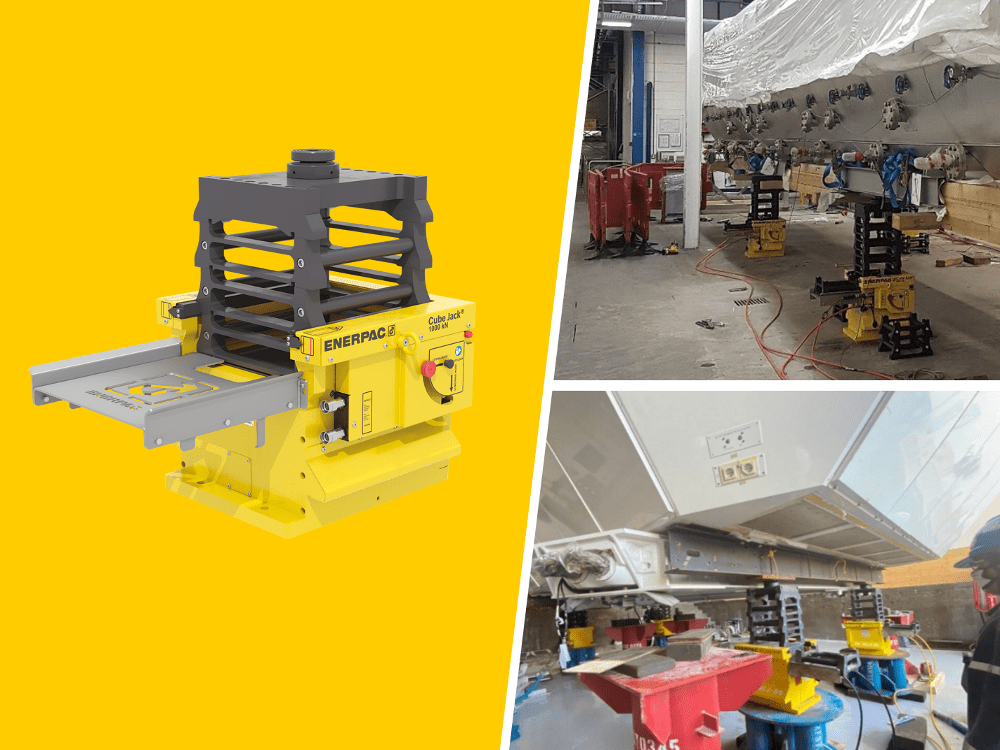

A jack-up system is a hydraulically powered solution for multi-point lifts. A typical setup includes four jack-up units positioned under each corner of a load. Unlike alternative systems that employ wooden cribbing blocks, they use steel barrels that are inserted, raised, and stacked to create lifting towers, enabling incremental lifting of the load.

Key Features

The essentials of a typical jack-up system are the four units, the software application, the smartbox software interface, steel barrels, and the top barrel which incorporates a swivel. Trolleys and tracks to enable horizontal travel are optional and can be controlled remotely.

Within each lifting unit are four powerful hydraulic cylinders, a cabinet housing the electrics, and the barrel insertion system, which depending upon the model, fetches the barrel automatically.

What Benefits Do Jack-up Systems Offer?

Put simply, a jack-up system provides accurate and synchronized multi-point lifting of large and heavy loads – typically those that need lifting from below. One alternative to this is using cranes, which usually take longer to mobilize and require more space. A second alternative is to use climbing jacks (stage lifts), but compared to a jack-up system, they do not provide the same safe lift heights, or resistance to sideload. Furthermore, the climbing jacks rely on cumbersome and unsustainable tropical hardwood cribbing blocks.

The benefits of a Jack-up System are summarized below:

• Allows lifting and lowering from below

• Lift towers can be built to reach impressive heights: e.g. 135ft (36m) can be reached when used with a suitable bracing system.

• Software controlled to provide synchronized accurate multi-point lifting and balance of the load

• Ideal for challenging access projects – e.g. can be installed on barges for bridge projects

• Small footprint of each unit

• Safe mechanical locking

• Self-contained hydraulics in each unit prevents a cluttered working area

• Fast and simple to transport and set up

Video

What Do Users Say?

We recommend reading what users have said to get a real appreciation of what jack-up systems offer. Here are a few examples:

Bridge Deck Installation

“The JS-250 jack-up system’s small footprint makes it advantageous for use in a confined construction site like we had here. At the request of the main contractor we needed to execute a test lift of all our equipment 48 hours before the final installation with SPMTs. Due to high winds, we were able to lower the bridge deck to a safer height without losing valuable time during the final installation preparations.”

Manuel Aertssen, business development manager, Aertssen Group

JS250 Used and SMPTs Transfer Bridge Deck to a Pontoon

“The jack-up was very stable and well within the lateral movement we’d allowed for the lift. It was also surprisingly quick. Raising and lowering the bridge deck was completed in a fraction of the time we’d expected.”

Roll-iT account & project manager Tom van Runckelen

Industrial Installation Project

“The Enerpac Jack-Up system is perfect for this kind of job, we

considered a gantry, but there was no space to move the gantry

forward to position the turbine and generator. The combination of the Jack-Up’s synchronized lift and skidding worked very well.”

Lincoln Collett, Technical Director, Collet & Sons Ltd.

Jack-up Systems in Action

Click and browse to see Jack-up Systems in action.

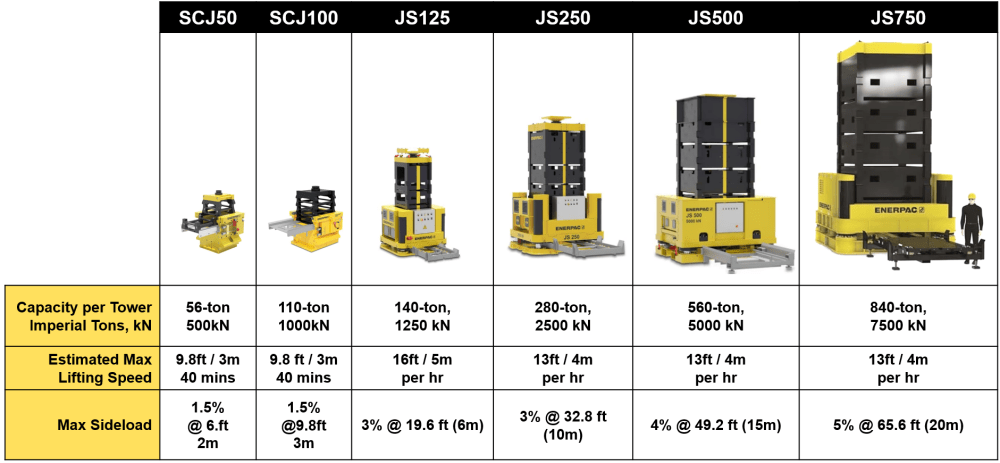

Enerpac Jack-up Systems Compared

Summary

As the need for accelerated bridge construction continues, hydraulic jack-up systems will continue to play a key role, thanks to their ability to offer accurate and safe multi-point lifting, quick mobilization, a small footprint, and efficiency improvements.

If you would like more information, please contact your regional heavy lifting specialist who will be happy to advise on your potential applications, product selection, and more detailed case studies.