7 Types of Bridges Every Engineer Should Know About

September 9, 2021

0

There are many different types of bridges, and each has its own advantages and disadvantages.

If you are an engineering contractor or civil engineer intending to work on bridge projects, here is a refresher of the basic principles behind each type. A quick read-through may help to ensure you’re well informed when discussing bridge projects with your colleagues and customers.

In case you were wondering, there is no single answer to the question ‘What is the best type of bridge?’ This is because many factors need to be considered, such as location, the span required, weight and volume of traffic, resources, and the budget available.

Below we have listed the 7 main types of bridges.

The Seven Main Types of Bridges

- Arch Bridges

- Beam Bridges

- Cantilever Bridges

- Cable-Stayed Bridges

- Suspension Bridges

- Tied-Arch Bridges

- Truss Bridges

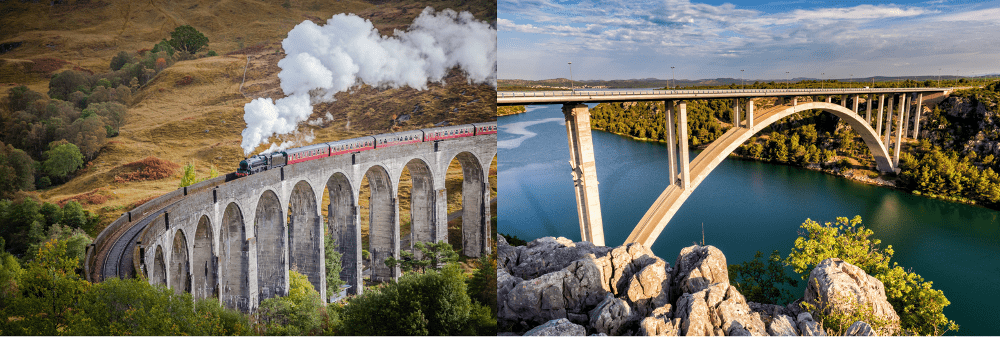

Arch Bridges

Arch types of bridges use one or more arches as the main structural component, with the arches positioned beneath the deck. This method dates back many thousands of years, with stone and brick being the most commonly used materials. However, in modern times you will see arch bridges constructed from concrete.

Whatever material is used the principle remains the same: An arch bridge uses compression – downward pressure from the deck travels laterally towards the keystone and to the supporting structures at each end of the bridge (the abutments).

Advantages of Arch Bridges

- High levels of strength and resistance (many Roman bridges still exist).

- Adapts to local environmental conditions well.

- Greater span compared to beam bridges (though less span than cantilever and suspension types).

- Can be constructed from many different materials; stone, brick, concrete, iron, and steel.

Disadvantages of Arch Bridges

- Creating a long span length requires more arches.

- Time-consuming to construct and maintain.

- Requires strong side support to complete a successful span.

- Requires considerable expertise to build.

Examples of Arch Bridges

- New River Gorge Bridge, Fayette County, West Virginia, USA.

- Rialto Bridge, Venice, Italy.

- Stari Most Bridge, Mostar, Bosnia and Herzegovina.

Beam Bridges

Beam bridges are the simplest type of bridge. In its most basic form, all that is needed is a crossbeam long enough to cover the span, and support from abutments under each end. To achieve a longer continuous span, (e.g., over 250 ft (80 m), piers need to be added to provide extra support. When doing this it means you create a series of bridges joined together.

A beam bridge may include several beams running in parallel to support the deck above. This is often referred to as a simply supported structure.

Advantages of The Beam Type of Bridge

- Simplicity and quick construction.

- Inexpensive (if no piers needed).

- Modules can be prefabricated away from the bridge location.

- Versatile – can be used in many locations.

- Multiple types of material can be used.

Disadvantages of Beam Bridges

- Limited span length between supporting structures.

- They can start to sag as they age (Weight limits are sometimes needed).

- Poor aesthetics.

- Costs are affected by fluctuations in steel prices.

- Maintenance and painting costs of steel bridges is expensive and time-consuming.

Examples of Beam Bridges

- Donghai Bridge: connects Pudong New area in Shanghai to Yangsang Deep Water Port in Zhejiang. 20.2 miles in length from one end to the other!

- Manchac Swamp Bridge, Louisiana, USA.

- Dhola Sadiya Bridge, over the Lohit River in India.

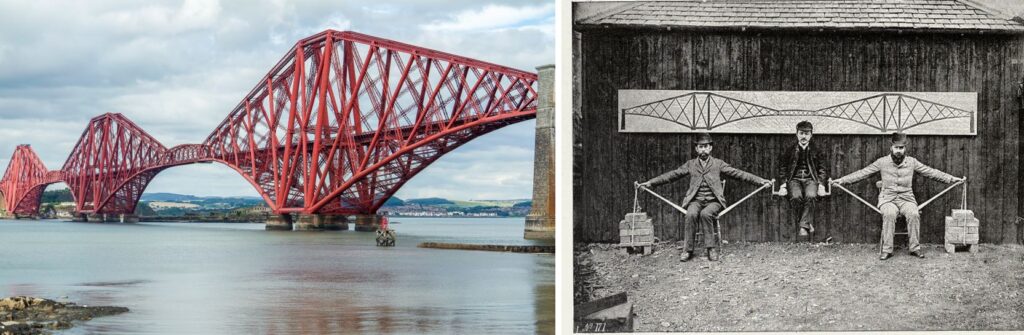

Cantilever Bridges

If you aren’t familiar with the cantilever principle, think of a diving board that is supported at just one end. A cantilever bridge is built using pillars securely anchored to the ground. The structure is then constructed outwards from each pillar with the horizontal beam often supported using diagonal bracing.

The famous picture above shows Forth Bridge engineers Sir John Fowler, Sir Benjamin Baker, and Kaichi Watanabe demonstrating the principle of the cantilever. In this example, Fowler and Baker are the cantilevers, and Watanabe represents the load on the suspended central span. The bricks on either end represent the anchor for the cantilever beams.

A cantilever bridge can be made using different materials, such as structural steel, or box girders of prestressed concrete for larger bridges that carry road or rail traffic.

Advantages of Cantilever Bridges

- A good method for creating long spans.

- Support is required only on one side of each cantilever.

- Suitable for deep rocky valleys and flood-prone areas where supporting structures cannot be built.

- Little or no disruption to traffic underneath the bridge.

- On bridges with multiple spans, the cantilevers can be built simultaneously to reduce time.

Disadvantages of Cantilever Bridges

- Complex to construct and maintain.

- Requires a heavy structure – so more material needed drives up the cost.

- Not suitable for excessive climate conditions or earthquake-prone areas.

- Experiences a high amount of tension during the construction (aka Negative moment).

- Stability relies on balancing compressive and tensile forces.

Examples of Cantilever Bridges

- Forth Bridge, Scotland, UK.

- Quebec Bridge, Quebec, Canada.

- Minato Bridge, Osaka, Japan.

Cable-Stayed Types of Bridges

The cable-stayed bridge dates back to the 16th century and remains a popular design for spans greater than those of cantilever bridges – but shorter than the longest suspension bridges.

This design uses deck cables connected to one or more vertical columns, towers, or pylons which can be connected in either a fan or harp configuration. Although the deck relies on the cables for support, this method should not be confused with the suspension bridge that uses vertical cables between the deck and the main support cable.

The most common build materials used in cable-stayed bridges are steel or concrete pylons, post-tensioned concrete box girders, and steel rope.

Advantages of Cable-Stayed Bridges

- Fast construction time compared to other bridge types.

- More rigid than suspension bridges.

- Cost-effective.

- Can be aesthetically pleasing.

- Multiple design options: (e.g., side-spar, cantilever-spar, multiple-span, cradle-system designs).

Disadvantages of Cable-Stayed Bridges

- Suitable for short to medium distances (Shorter span than suspension bridges).

- Difficult to access in some areas, which means higher-than-average costs of maintenance.

- Cables can be prone to corrosion and high levels of fatigue.

- Easier to vandalize (by cutting cables).

- Not suitable for excessive climate conditions or earthquake-prone areas.

Examples of Cable-Stayed Bridges

- Millau Bridge, Occitanie, France.

- Queensferry Bridge, Scotland, UK.

- Jiaxing-Shaoxing Sea Bridge (Jiashao Bridge), China.

Watch the video below to learn more about the construction of the Millau Bridge

Suspension Bridges

The principle of a suspension bridge is not new – early designs simply used rope and wooden planks. Today, they are a popular design for long road bridges – thanks to the ability to create large spans across broad channels. Probably the most famous of all is the Golden Gate Bridge in San Francisco, US.

A suspension bridge uses vertical towers or pylons constructed from steel or reinforced concrete.

Attached Between the pylons are the main supporting cables. These cables are made from galvanized steel wire, and including their casing, can measure as much as 36 3/8 in (0.92 m) diameter. The Golden Gate suspension bridge is arguably the world’s most famous suspension bridge and is one of the most photographed. The American Society of Civil Engineers voted this as one of the Seven Wonders of the Modern World.

Advantages of Suspension Bridges

- The best bridge type for creating the longest spans with minimum piers.

- Regarded by many as aesthetically pleasing – creating a landmark for the community.

- The waterway can be left open while the bridge is under construction – (almost all of the work takes place on the top of the bridge).

- Flexibility – design allows for deck sections to be replaced.

- Can be built with a high deck, allowing plenty of clearance for passing ships.

Disadvantages of a Suspension Bridge

- Not as robust as some bridge types.

- A combination of vertical pressures and extreme side wind speeds can lead to a failure of the span.

- High winds can cause a suspension bridge to start vibrating.

- They can struggle to support focused heavy weights (e.g., trains).

- Failure of just one cable can be enough to cause the entire bridge to collapse.

- Access below the deck is difficult during construction and maintenance.

- Some suspension bridges require extensive foundation work if the ground is soft.

Examples of Suspension Bridges

- 1915 Çanakkale Bridge, Turkey.

- Humber Bridge, England, UK.

- Golden Gate Bridge Suspension Bridge, San Francisco, US.

Tied-Arch Bridges

A tied-arch or bowstring bridge uses features seen in both a suspension bridge and an arched bridge. However, unlike a traditional arched bridge, the arch is positioned above the deck and uses vertical cables attached to support the deck.

This arch (or bow) uses the tension of its vertical cables, together with the compression of the arch, to support the load – keeping the bridge very stable.

Advantages of Tied-Arch Bridges

- Very strong.

- Less force on abutments.

- Can be built off-site and transported into place.

Disadvantages of Tied-Arch Bridges

- Regular maintenance is required to ensure the stability of the hangers and arch.

- If one hanger breaks the entire structure can be adversely affected.

- The size of each span is limited as compared with suspension bridges

- More expensive to build as compared with other types of bridges the same length.

Examples of Tied Arch Bridges

- Fort Pitt Bridge, Pittsburgh, Pennsylvania, USA.

- Clyde Arch Bridge, Glasgow, UK.

- Puente de la Barqueta, Seville, Spain.

Truss Bridges

There are many different configurations of a truss bridge, but you will notice they all use triangular sections typically bound together by welded or riveted joints. The trusses are constructed vertically and horizontally which absorb tension and compression. The end result is a structure and decking area capable of withstanding relatively strong winds.

The truss design is reasonably inexpensive and has been around for a long time. In the early days during the 19th century, most were built of wood, before later shifting to iron and steel.

Advantages of Truss Bridges

- The strongest type of bridge.

- Can be built off-site and quickly installed on location.

- Lighter than other bridge types.

- Economical.

- Withstands extreme weather conditions.

- Versatile – able to carry its roadway above (deck truss), along the middle (through truss), or on a lower truss sitting below the major structure.

Disadvantages of Truss Bridges

- Truss bridges require perfect construction to work. They must distribute weight evenly.

- Older truss bridges designed for light traffic can have a lower weight tolerance.

- Requires a lot of space. Interconnecting triangular components need to be large to bear and distribute heavy loads.

- There are width requirements in relation to span length to achieve the required strength

- Less attractive to look at compared to modern concrete bridges

- Requires architectural and engineering specialists – less use of general laborers and steelworkers.

Examples of Truss Bridges

- Tokyo Gate Bridge, Kōtō City, Japan.

- Astoria-Megler Bridge, Columbia River, USA.

- Quebec Bridge, Canada.

Update 2023

The 7 types of bridges covered above represent the main configurations, but there are many variations within each category and some interesting hybrid designs.

Moveable Bridges

A bridge may need to be moveable to allow the passage of tall ships and other vessels that would otherwise not be possible with a fixed bridge. Moveable bridge types include:

Bascule Bridge: A type of hinged bridge that uses counterweights to assist in raising the deck.

Vertical lift bridge: Includes a deck section lifted by counterweights and cables attached to towers. The rising deck section remains parallel to the other deck sections.

Table Bridge: With the same action as a vertical lift bridge, but using hydraulic pillars beneath each corner of the deck section to carry out the lifting.

Tilt Bridge: Mostly used for pedestrian bridges. A tilt bridge is horizontally bow-shaped, and when rotated provides greater clearance for river traffic passing underneath.

Retractable Bridge: A rare configuration of bridge that rolls or slides the deck backwards. Examples include the Carroll Street Bridge in Brooklyn, New York, and the Queen Alexandra Dock in Cardiff, Wales, UK.

Folding Bridge: Uses a concertina action, creating an inverted Z shape as it is retracted.

Swing Bridge: A bridge that remains at the same height but rotates to create a passageway for river traffic.

Transporter Bridge: Also known as a ferry bridge. Lifts and carries a bridge section across a waterway and using cables and pulleys.

Pontoon Bridge: A Pontoon is a floating bridge that uses groups of floats or barges connected together to support the deck. These are mostly temporary structures used on military or infrastructure projects.

Through Arch Bridge

A through arch bridge includes arches across the whole span of the bridge, with sections rising above and extending below the deck. The advantages of this type of structure include the ability to span long distances while requiring fewer supporting piers. Additionally, the through-arched bridge provides generous clearance underneath, which makes them ideal for waterways used by tall vessels. The most iconic of these is the Sydney Harbour Bridge in Australia.

Box Girder Bridge

A girder bridge, or box section bridge includes beams in the shape of a hollow box. The box sections are normally made from prestressed concrete, structural steel, or a combination of the two. You will see box girders used on highway flyovers which may also be beam bridges or cable-stayed bridges.

Cantilever Spar Cable-Stayed Bridge

This is a modern take on the traditional cable-stayed bridge, but with a difference. Instead of a vertical spar/pylon, this variant of bridge uses an angled spar that acts as a cantilever.

Covered Bridge

A bridge may be covered to protect the timbers from harsh weather conditions. Added benefits of covering the deck can be an aesthetic appeal and extra stability.

Extradosed Bridge

A bridge structure that combines the elements of prestressed box girder and cable-stayed designs.

Trestle Bridge

A trestle bridge includes short spans supported by rigid frames (trestles) positioned closely together. These are traditionally constructed from timber, but more contemporary models use steel or concrete.

Truss Arch Bridge

As the name suggests, this type combines the rigid characteristics of a steel truss bridge, but applied to an overall arch bridge structure.

Plate Girder Bridge

A plate girder bridge typically uses two i-sectioned beams running parallel across the span. The i-beams are made from vertical and horizontal steel plates, which are either welded or bolted together. These are prefabricated away from the bridge, so the span lengths are dictated by the limitations of the transport method.

Spiral Bridge

Also known as a loop bridge or pigtail bridge, this configuration follows a helix shape and therefore loops over its own road. The purpose of this kind of bridge is to create a route from one height to another by using a small footprint. You often see spiral bridges in multi-storey car parks and highway interchanges.