23 Tips for Using Hydraulic Tools Safely

July 6, 2022

0

When used correctly, hydraulic power is one of the safest methods of applying force to your work. But the consequences can be severe if you don’t take precautions and follow the right procedures.

Some fundamental guidelines include…

- When lifting a heavy load, lift it slowly and check it often.

- Avoid standing in the line of force.

- Anticipate potential problems and take steps to avoid them.

- Check to see if all safety measures have been taken.

Also, you can prevent many accidents using some simple safety DO’s and DON’Ts.

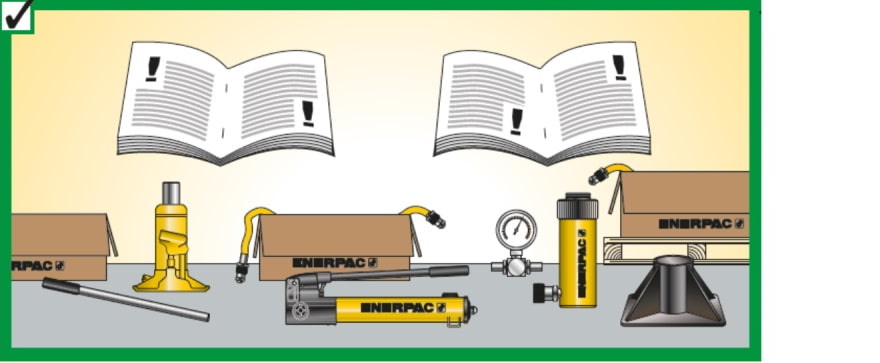

You may be new to hydraulic tools, or perhaps you’re an experienced engineer looking to refresh your safety knowledge. Either way, we recommend you review these DOs and DON’Ts which apply not only to cylinders and jacks, but also to many other hydraulic products. If you prefer, you can also download a 2-page PDF for offline viewing or printing.

Jump to sections

Part 2 Safety with Hydraulic Jacks

Part 3 Safety with Hydraulic Cylinders

Part 5 Hydraulic Hoses and Couplers

Part 1: General Safety Tips

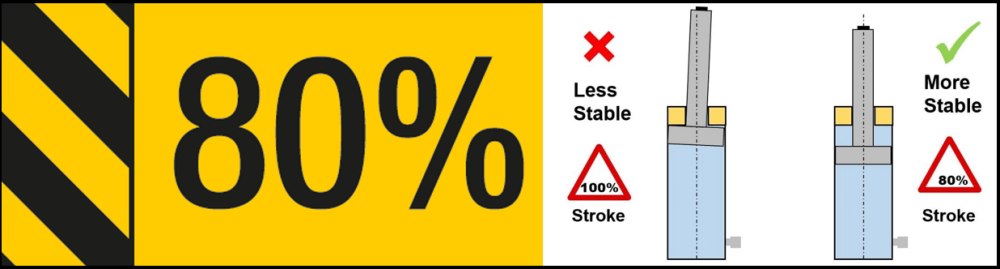

- The Manufacturer’s rating of load and stroke for products are the maximum safe limits. It is good practice to use only 80% of these ratings!

2. Ensure you always read the instructions and safety warnings with your hydraulic equipment.

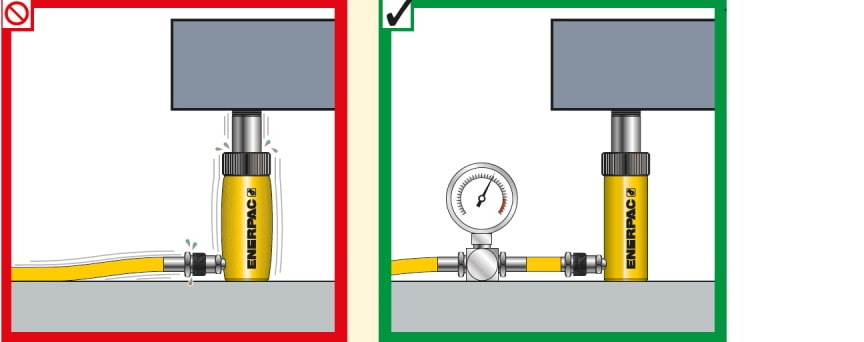

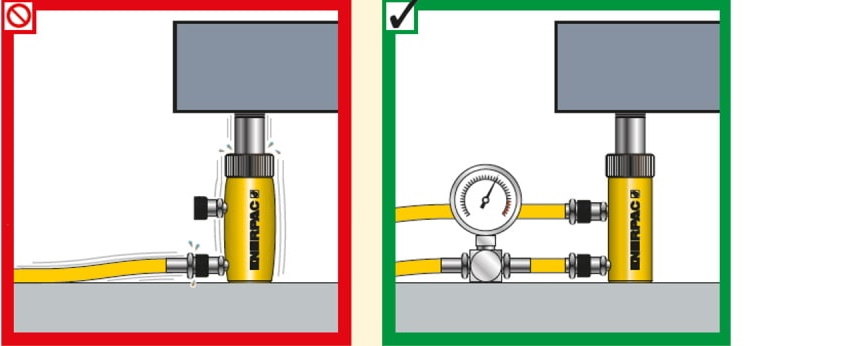

3. Never override the factory setting of relief valves. They are included to keep you safe! Also, when working with hydraulic tools you should always use a gauge to check the system pressure. You can find out more about this in our article “Why Use a Hydraulic Pressure Gauge”

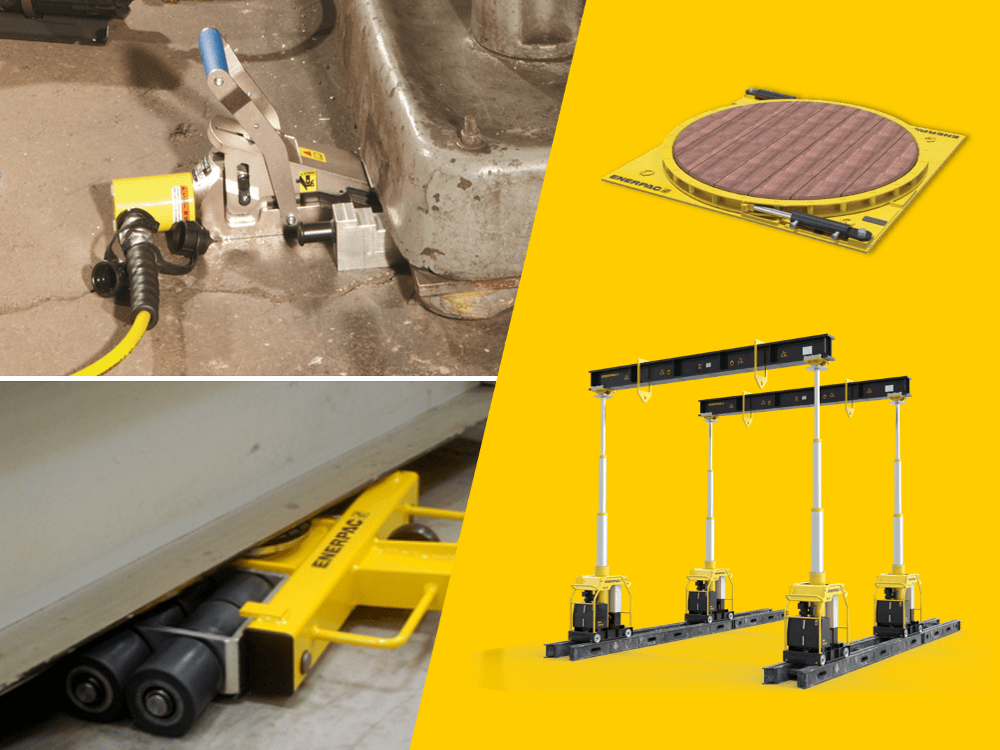

Part 2: Safety with Hydraulic Jacks

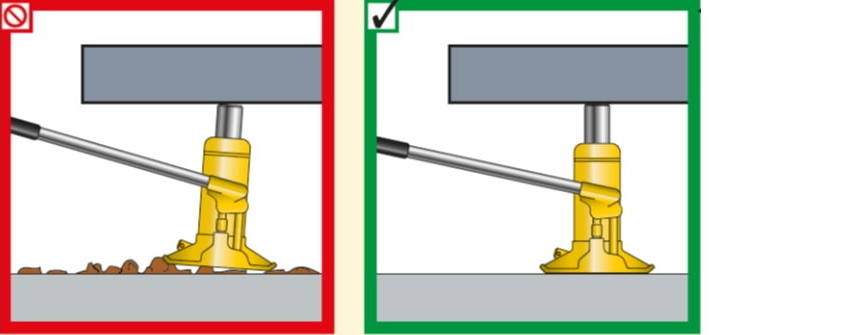

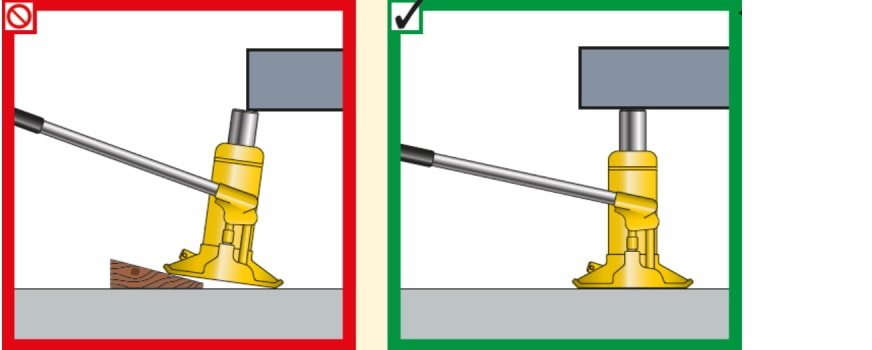

4. Make sure you always provide a level and solid support for the entire jack base area.

5. The entire saddle on the jack must be in contact with the load. Ensure that the movement of the load is in the same direction as the plunger on the jack.

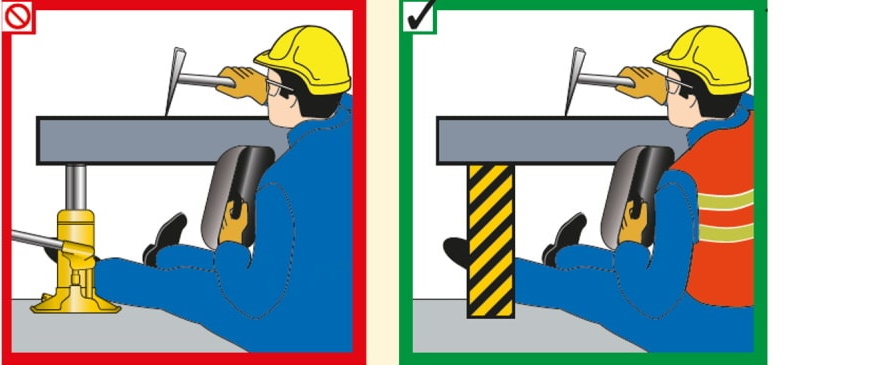

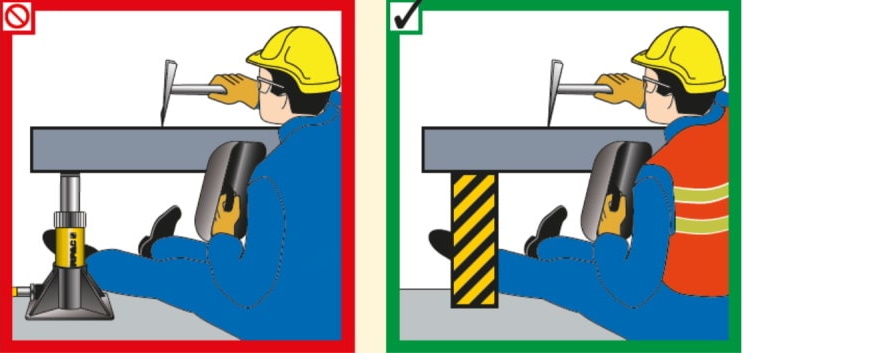

6. No matter how confident you are in the tools and setup, avoid placing any part of your body under the load.

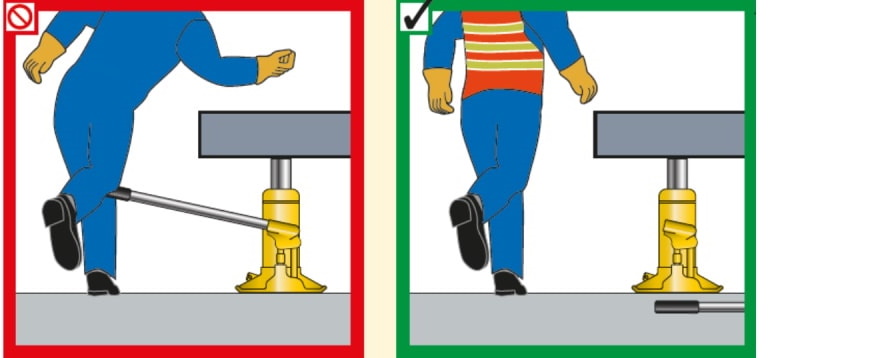

7. If you are not operating the jack and it remains in-situ, remove the jack handle to avoid injury and trip hazards.

Part 3: Hydraulic Cylinder Safety

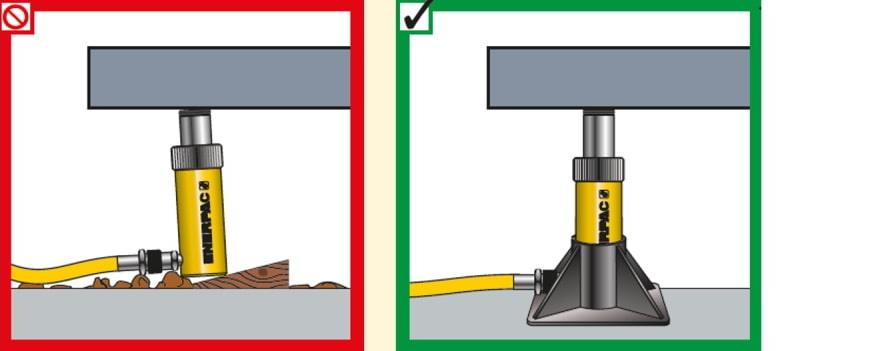

8. Provide solid and level support for the entire cylinder base area. Using a cylinder base attachment helps to provide more stability. See cylinder bases.

9. When using double-acting hydraulic cylinders, ensure couplers and a return hose are fitted and connected.

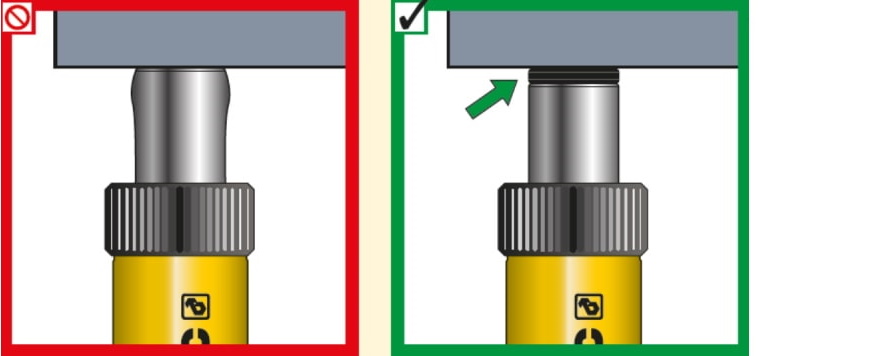

10. Don’t be tempted to use a hydraulic cylinder without a saddle. Doing so may cause the plunger to ”mushroom”. A saddle protects the plunger and distributes the load evenly on the plunger. Consider a tilting saddle, which can help to reduce side load damage and extend the life of the cylinder

11. As with jacks, never place any part of your body under the load. The load must be on cribbing before venturing under.

12. Keep the attachment threads on top of the cylinder in good condition. Protect cylinder threads for use with the cover provided.

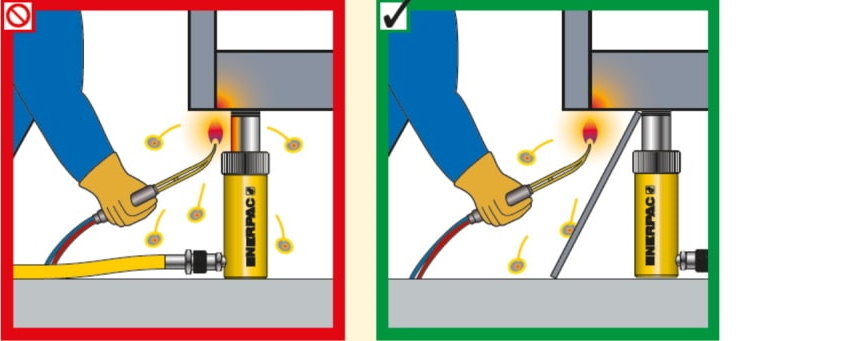

13. Keep your hydraulic equipment away from open fire and temperatures above 65 °C (150 °F). High temperatures can place stress on the internal components and lead to hydraulic system failure. The lubricants may also lose viscosity making them less efficient. Oxidation can also occur.

Part 4: Using Hydraulic Pumps Safely

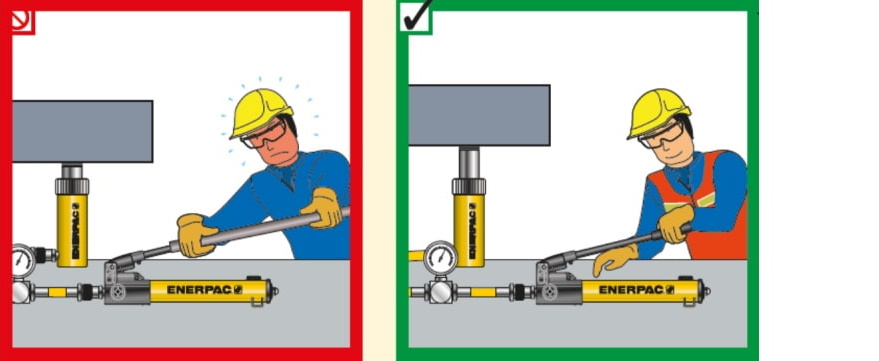

14. Don’t use handle extenders. If everything is set up correctly, the correct hand pump should be easy to operate. View manual pumps.

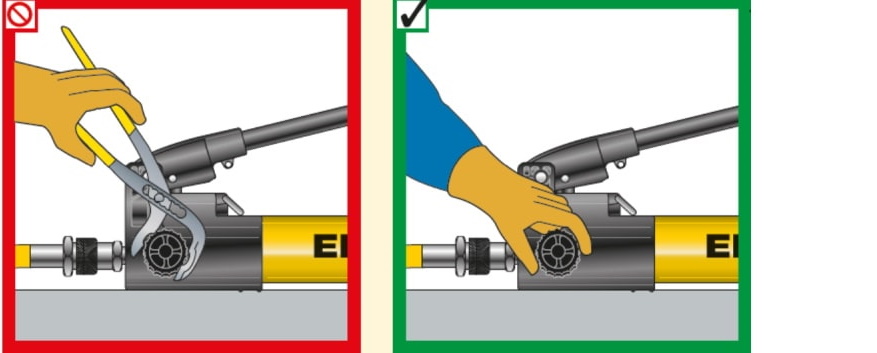

15. When opening and closing the release valve, do this finger tight only. Using excessive force will ruin the valve.

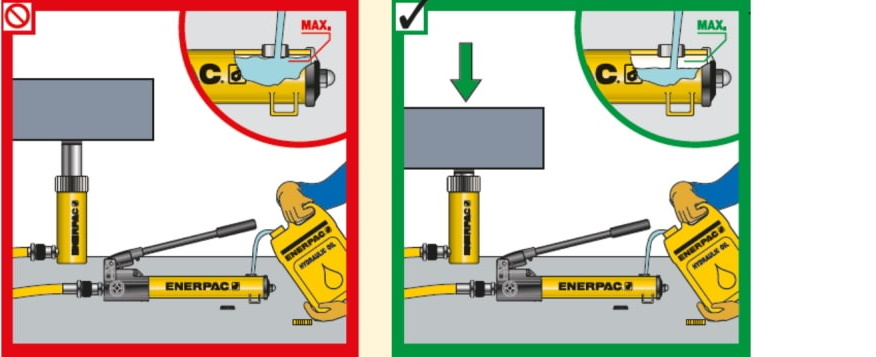

16. You should only fill the pump up to the recommended level. Fill only when the connected cylinder is fully retracted.

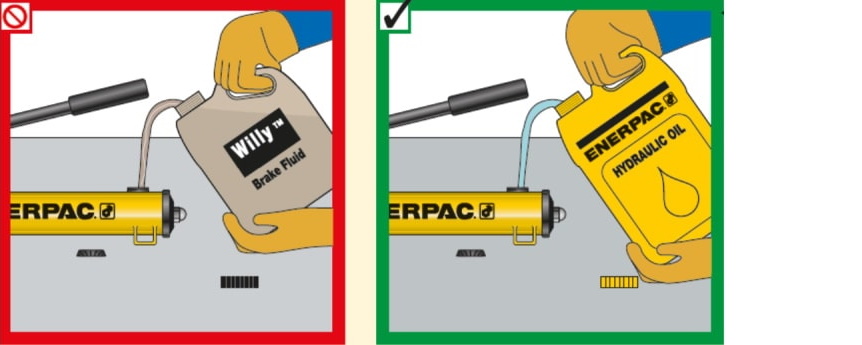

17. Use only genuine Enerpac Hydraulic Oil. The wrong fluid may destroy seals and the pump. It may also render your warranty null and void your guarantee.

Part 5: Hoses and Couplers

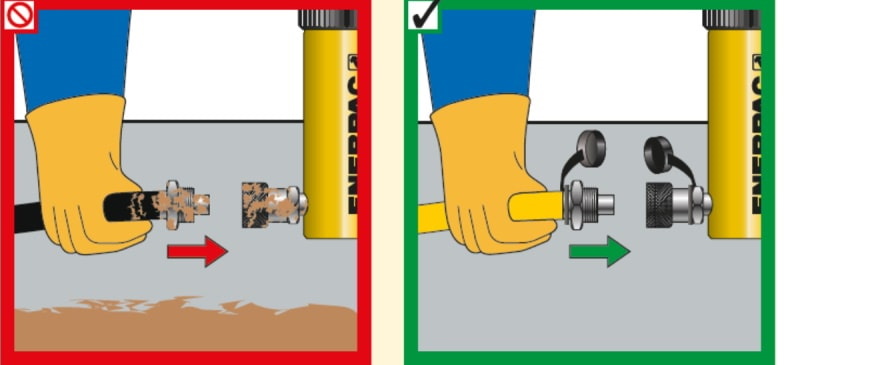

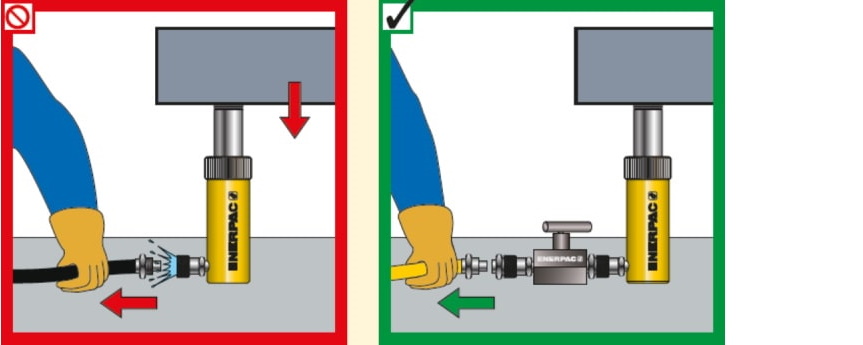

18. Do not allow dirt to contaminate the hydraulic system. Make sure both coupler parts are clean before connecting. Use dust caps whenever the coupler parts are not connected.

19. Only detach a cylinder after it is fully retracted, or use shut-off/safety valves to lock in the cylinder pressure.

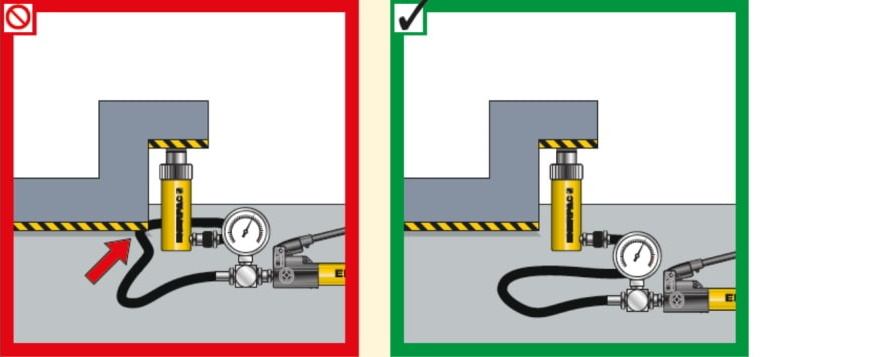

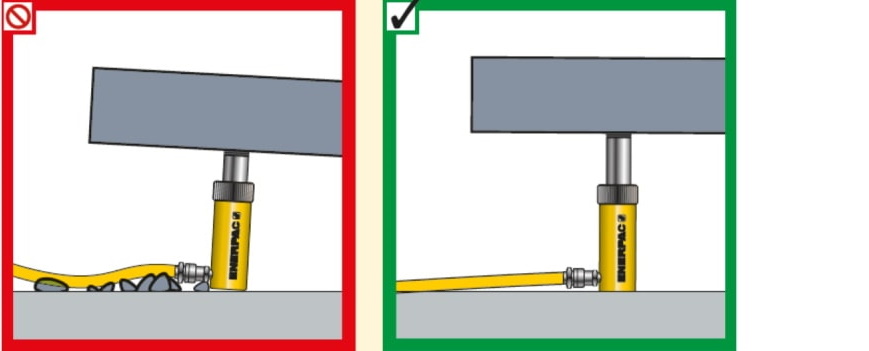

20. Protect your hydraulic hoses by keeping them away from the area beneath the load.

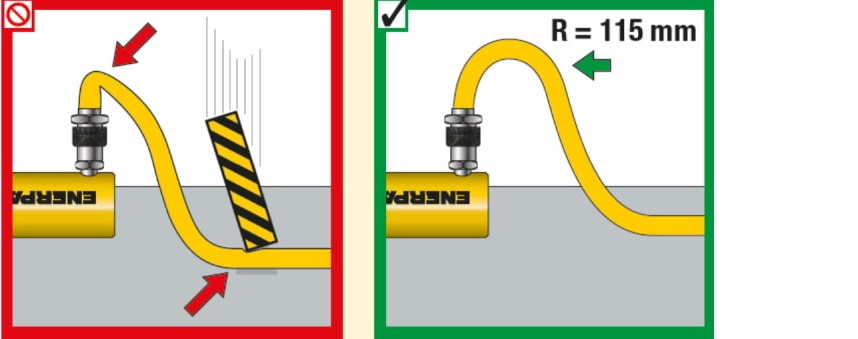

21. Do not kink or bend hydraulic hoses too tightly. The bending radius should be at least 115 mm. (4.5 inches). Also, don’t drive over or drop heavy objects on your hoses.

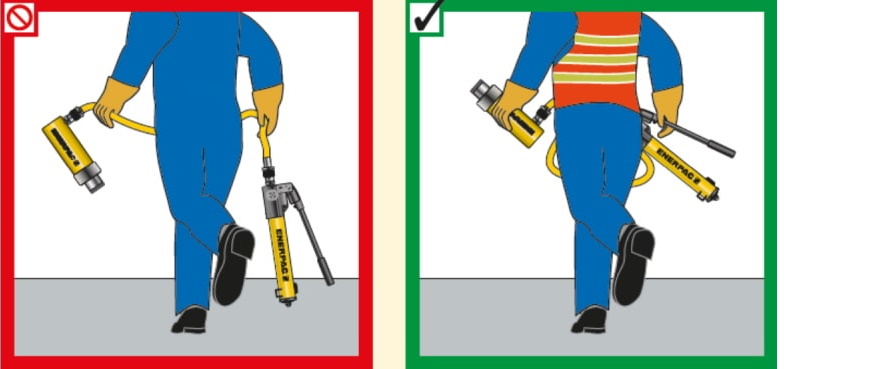

22. Don’t put unnecessary strain on your hoses and couplers. Don’t lift your hydraulic equipment by the hoses.

23. Never allow the cylinder to be lifted off the ground through the couplers.

Enerpac can not be held responsible for damage or injury, caused by unsafe use, maintenance, or application of our products.

If in doubt as to the proper safety precautions to be taken when designing and setting up your particular system, please contact the Enerpac office or a representative for guidance.

In addition to these tips, every Enerpac product comes with instructions spelling out specific safety information. Please read them carefully.