Why Use a Hydraulic Pressure Gauge?

February 15, 2021

0

When working with hydraulic tools, a hydraulic pressure gauge is an essential component to include in your pressure system.

But all too often, people are still tempted to simply hook up their cylinder to the pump, cross their fingers, and assume everything will be ok. Doing this puts yourself, your colleagues, and the whole project at risk.

So, how does a hydraulic pressure gauge help? And how do you choose the correct one for your application?

Reasons to Use a Hydraulic Pressure Gauge

Working without a hydraulic pressure gauge is unpredictable. You are working ‘blind’ and totally unable what might happen next.

Improved Visibility

A pressure gauge provides a window into the system. If there’s a problem, it will show you when it is safe to carry out investigative activities, such as checking hose connections.

Effective Troubleshooting

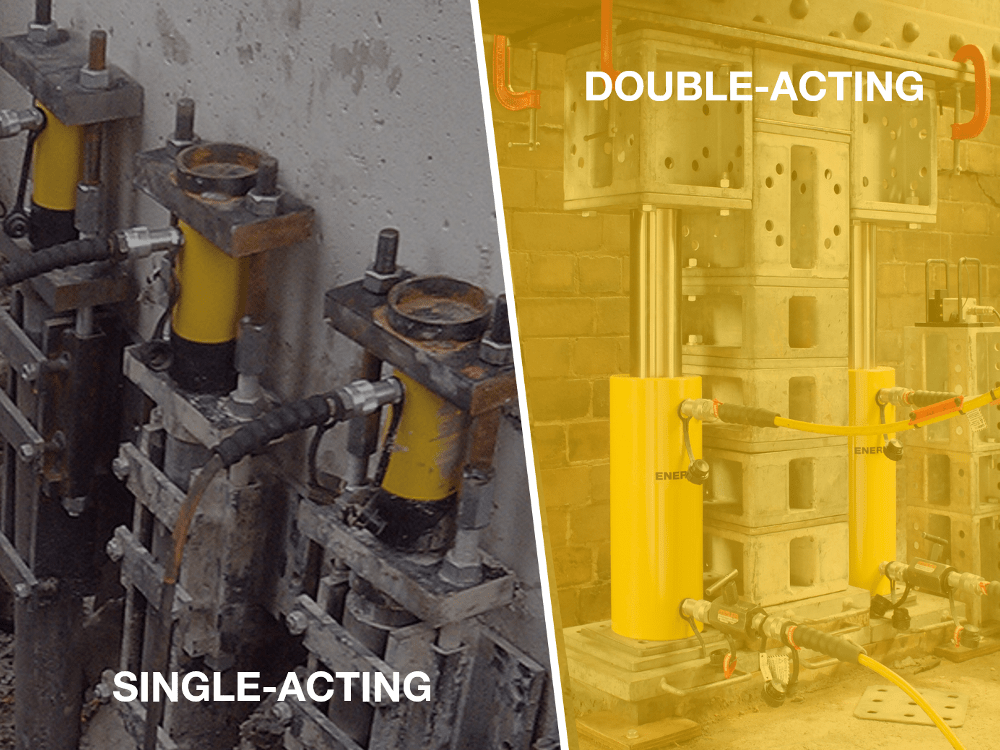

Gauges are essential when troubleshooting: Imagine you are using hydraulic cylinders to lift a load, but you find that the load won’t go up. The gauge can tell you if there is enough pressure at the pump and that the pump is working ok. If this was the case you would know that the problem lies elsewhere. |For example, the cylinder may be too light for load, or the load is heavier than expected.

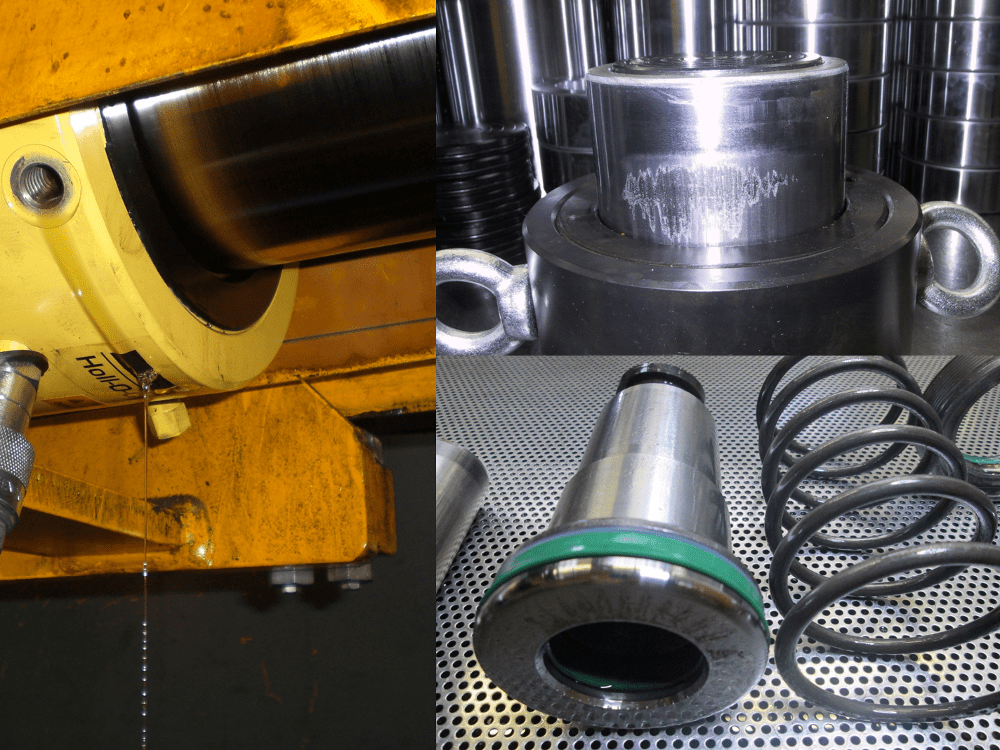

Spot Leaks and Blockages

If leaks or blocks occur in the circuit, the system pressure will reduce and you will see this in the gauge. Technicians can then identify the reason for that pressure drop and repair it immediately.

Prevent Hazards

Using the right gauge will help to prevent many hazards. E.g., exploding gauges, leaking hydraulic fluid, injury from pressurized connections, or the load from falling.

Reassurance

Even when there isn’t a problem it’s good to have the confidence that all is well!

How to Choose the Right Pressure Gauge

The main types of pressure gauges are dry, digital, and glycerine filled. For many on-site hydraulic applications, a glycerine filled gauge is the best choice.

Why use a glycerine filled gauge?

The glycerine inside the gauge dampens the effects of sudden changes in pressure. This helps to protect the mechanics inside the gauge. They are ideal for applications where there could be ‘shock loads’ and sudden pressure changes in the system. (For example, when using hydraulic nut splitters). A glycerine gauge should also be used with powered pumps because the glycerine dampens needle vibration – enabling better readability of the gauge and prolonging its usable life.

Other key considerations when selecting a hydraulic pressure gauge

What pressure range is needed? – Make sure you match gauge to the pressure of the job. For example, reading 25 bar on a 1000 bar gauge won’t be very accurate. Also, a gauge designed for a lower pressure than your application is likely to break.

Pressure and force – some gauges include a scale displaying force as well as the pressure. For example, for a lifting project, a Force Gauge can measure the load supported by a cylinder or jack.

Scales: These are available in imperial and metric versions.

Accuracy required: +/- 1.5% accuracy of the full scale is common, however, +/- 0.25% can be achieved with a digital gauge. Make sure to select a gauge with the correct accuracy.

Choice of material: For the casing, copper alloy is common for lower pressures. Stainless steel is often used for high pressures. It is worth checking the material will be suitable to use if you will be working in harsh environments.

Mounting options: Gauges have a threaded mount with options available that include lower, rear, centre rear.

Threads: Make sure you choose a gauge with the right thread on the mount (e.g., ½ or ¼ NPTF).

If you choose a manufacturer who offers gives a wide range of gauges to choose from, selecting the right one will be an uncomplicated process. The Enerpac website shows you the cylinders that are compatible with each gauge.

Options and Accessories

In addition to the gauge, consider the following.

Mounting options

A gauge adaptor lets you connect to the hydraulic system. These are also pressure rated. A typical adaptor will have a male end that screws into the pump or cylinder port, and a female end that accepts a hose or coupler. The third port is for the gauge connection.

Snubber Valve

Gauge snubber valves suppress the effect of pressure pulses and peaks, which are common reasons for gauge failure. They are especially recommended for high cycle applications. The V91 type available from Enerpac is infinitely adjustable for metering oil out of a gauge, preventing snapping of the gauge pointer when load or pressure is suddenly released. This type can also be used as a shut-off valve to protect the gauge during high cycling applications.

Shut off valve

Does exactly what the name suggests. One example is the stainless steel NV251, Gauge Shut-Off Valve ¼ inch.

Auto-Damper Valve

As with a snubber valve, the V10, Auto-Damper Valve is another simple fitting used to creates flow resistance when load is released suddenly. The simple design means that no adjustments are necessary.

Connecting pressure gauges safely

Install your hydraulic pressure gauge where it is easily readable but well protected against damage from external sources. This is typically near the pump.

When making hydraulic connections, use high quality sealing compound on the threads of the male fittings only. If you use Teflon tape, use this sparingly and do not tape the first thread. Be aware that loose Teflon tape inside your pump or cylinder can cause malfunctions and damage.

The gauge should be operated at pressures that do not normally exceed 75% of the full scale.

Where do I go for help?

If you need guidance selecting the right gauge you can get in touch with Enerpac via the website. Approaching your local distributor is the other option but be aware that some are more experienced in hydraulics than others. Make sure they are suitably experienced and qualified enough to advise you.

Disclaimer

Hydraulic tools can be dangerous and should only be used by suitably qualified people. This article is intended to provide a simple overview explaining the importance of using a pressure gauge and is not an operational guide.