Single vs 2 Speed Hydraulic Hand Pumps: How to Decide

April 26, 2022

0

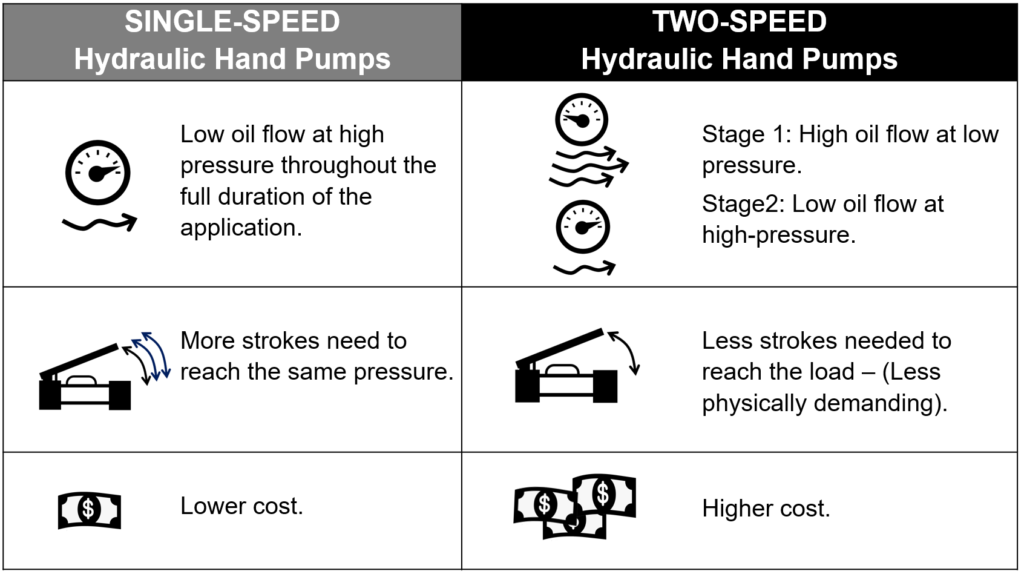

If you need a hydraulic hand pump one of the most fundamental things to understand is whether you need a single-speed or 2 speed hydraulic hand pump.

So, what’s the difference and how do you decide? – Let’s take a look at both types.

What are Single-Speed Hydraulic Hand Pumps?

A single-speed hydraulic hand pump is a simple and relatively low-cost option. As you pump the lever, the hydraulic oil is drawn from the pump’s reservoir towards your hydraulic tool – (which may be a hydraulic cylinder, ram, puller, or a press).

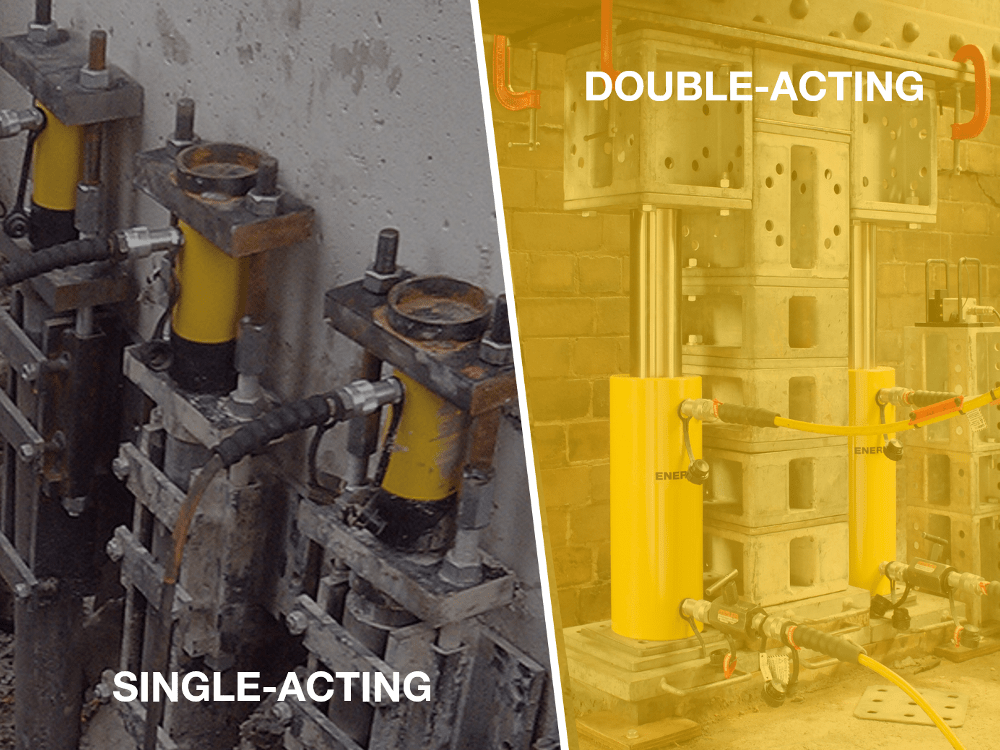

When using a single-speed hydraulic pump with a tool such as a cylinder, the plunger will advance by the same amount with each stroke of the pump’s handle. The reason for this is because the amount of oil displaced per full stroke is always the same.

For many applications, this is exactly what’s required. But for projects where a cylinder or other tool needs to extend large distances this can be too time-consuming and tedious. This is when a two-speed pump can save the day.

What are 2 Speed Hydraulic Hand Pumps?

A 2 speed hydraulic hand pump switches from an initial low-pressure, high oil displacement stage to a low-displacement, high-pressure stage.

When used with a hydraulic cylinder, this means the greater oil flow in the first stage moves the cylinder plunger a longer distance with each stroke. When it reaches the changeover pressure, the two-speed pump switches from low to high-pressure pistons – typically when the cylinder reaches the load and starts working harder

A two speed hydraulic hand pump can be more advantageous than a single-speed one for applications such as pressure testing, hydraulic presses, and long-stroke cylinders. However, they aren’t suitable for jobs requiring high pressure ‘all the way’.

Single-Speed vs 2-Speed Hand Pump Comparison

Summary

A single-speed hydraulic pump provides low flow with high pressure – which is usually fine for smaller stroke hydraulic cylinders, flange spreaders, and pullers.

A two-speed hydraulic hand pump creates high flow at lower working pressures and can also provide lower flow when it reaches the higher working pressures. This is especially useful when the cylinder plunger or other hydraulic tool has far to travel before the real work begins. Compared to a single-speed pump, some two-speed types can reduce the number of handle strokes by as much as 78%.

Both types of pumps are available with different oil capacities, and in configurations to suit tools requiring both single and double-acting hydraulic flow.

See the full range of hydraulic hand pumps on the Enerpac Website.