Single-Acting vs Double-Acting Hydraulic Cylinders

March 9, 2021

0

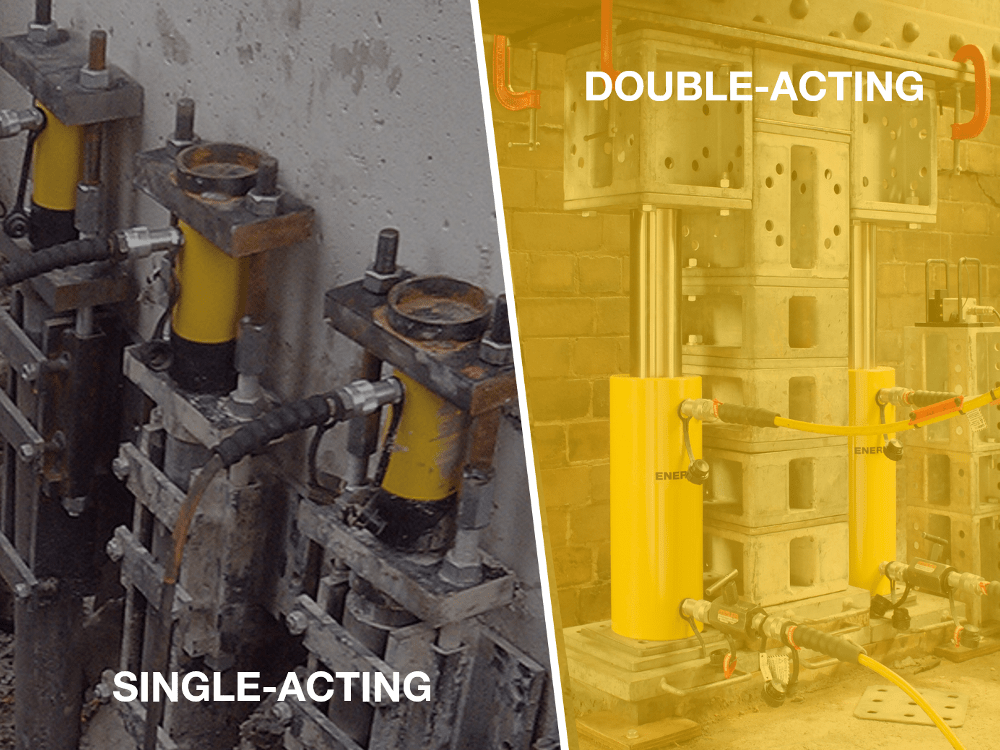

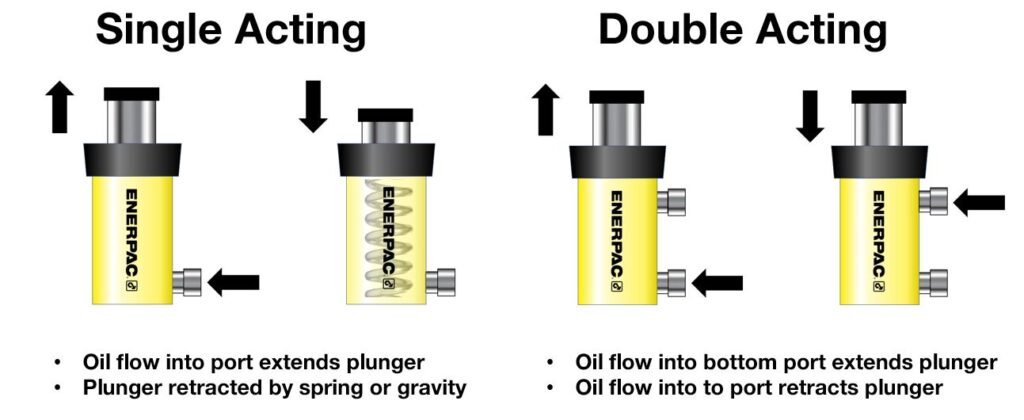

When comparing single-acting vs double-acting hydraulic cylinders, the most visible difference is the number of couplers or connection ports. A single-acting hydraulic cylinder includes just one port. This is where the hydraulic fluid enters and forces the plunger out in one direction. A double-acting cylinder includes two ports. One for the hydraulic fluid to enter and extend the plunger, and the other for retracting the cylinder.

Differences in how they work

The plunger in a single-acting hydraulic cylinder extends when hydraulic fluid under high pressure is pumped into the cylinder. When it is time to retract the cylinder, depending upon the cylinder design, the plunger can be retracted using a return spring, by the load, or simply by gravity.

In a double-acting hydraulic cylinder, the plunger retracts when hydraulic fluid is pumped under high pressure into the top port, forcing the plunger back to its original position. This can be done quickly, if required, or very gradually with precise control.

Single-Acting Hydraulic Cylinders

The single-acting cylinder is simpler than its double-acting counterpart. With fewer components, there is much less to go wrong, which is good news when it comes to maintenance.

Single-acting cylinders are ideal for straightforward jobs – especially when fast or controlled retraction isn’t essential. Hollow plunger versions including a thread are also available to handle pulling applications.

Double Acting Hydraulic Cylinders

Double-acting hydraulic cylinders have the ability to pump hydraulic fluid to both sides of the plunger. Connection ports positioned near both ends allow the piston rod to move both forwards and backwards. The extra port also allows more control of the plunger during retraction and ensures it always returns back to its starting point.

The faster and predictable retraction of double-acting cylinders makes them the better choice for projects needing repeatable accuracy.

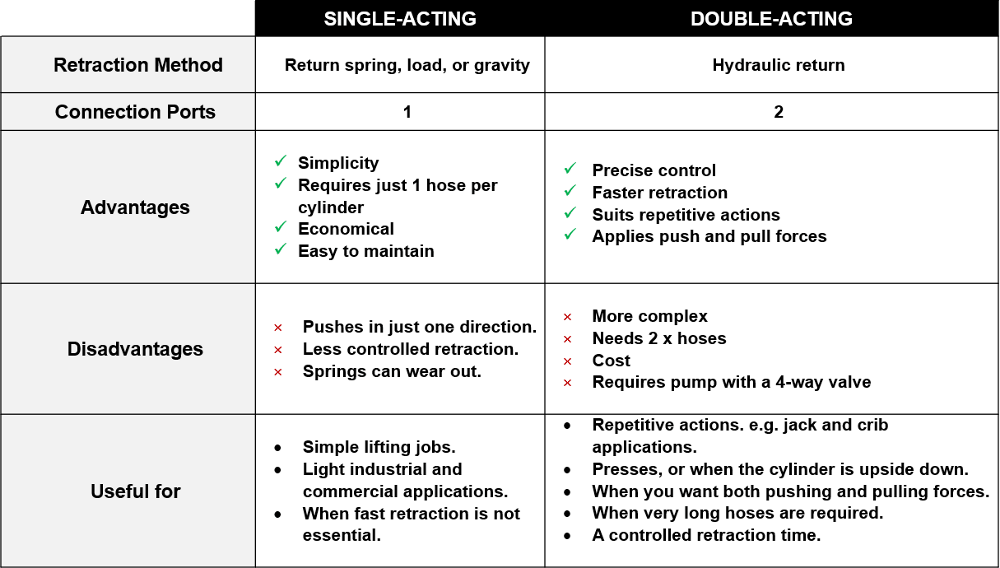

Comparison Table: Single-Acting and Double Acting Cylinders

Check out the table below to see how the different types compare.