‘Set Torque Accuracy’ vs ‘Full-Scale Torque’ – What’s the Difference?

May 1, 2024

0

When considering torque wrench accuracy, you may encounter two different specifications; ‘full-scale torque’ and ‘set torque’. So if a manufacturer claims their torque wrench provides +/- 5% accuracy it’s important to know which method they are using and what the difference is.

What is full-scale torque wrench accuracy?

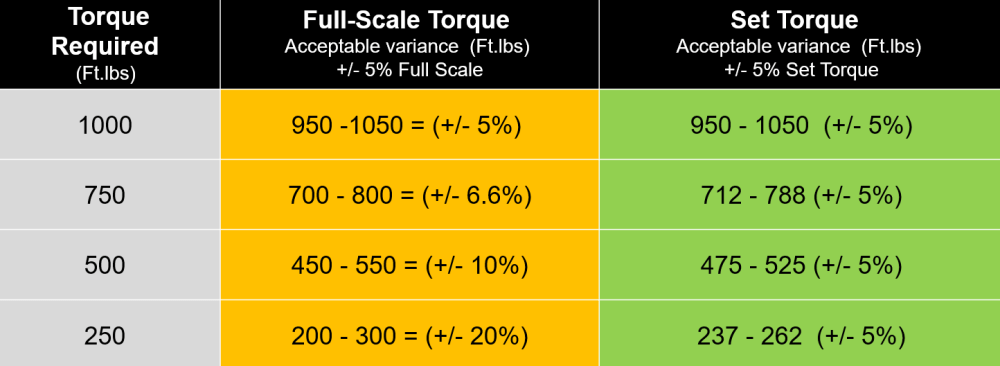

Full-scale torque defines the accuracy at the maximum torque capacity. For example, if a manufacturer states +/- 5% accuracy using ‘full-scale torque’, this means if the torque wrench is used at its maximum of let’s say 1,000 Ft.lbs, the acceptable range is within +/- 50 Ft.lbs.

While this may be acceptable at higher torque values, applying the full-scale torque allowable accuracy range of +/- 50 Ft.lbs at the lowest torque value means the actual applied torque may vary by as much as +/- 20%!

So when using a torque wrench from a manufacturer that uses the full-scale torque wrench accuracy method, be aware that the lower the applied torque, the more likely it will be less accurate in percentage terms.

What is set torque accuracy?

When a manufacturer uses set torque as the measure of accuracy, (sometimes referred to as indicated value), this means the torque wrench will deliver torque within the same percentage accuracy range, e.g. +/- 5% no matter how high or low the wrench is set in the usable range.

So, at the maximum usable torque value, full-scale and set torque accuracy both offer a similar level of accuracy.

But with a consistent +/- 5% throughout the whole usable range of torque, the set torque standard becomes the clear winner by far – especially when using lower torque settings!

Why does it matter?

If you have a specific torque value and tolerance that must be achieved, a torque wrench with ‘set torque’ accuracy gives you more peace of mind. It will ensure that the correct amount of torque is applied to meet the specifications of the application, such as manufacturer recommendations or engineering standards.

In precision applications where torque accuracy is critical, such as in power generation, automotive, aerospace, oil & gas, or manufacturing industries, achieving the exact set torque is essential to ensure the integrity, safety, and performance of the assembled components.

Where can I get a torque wrench with set torque accuracy?

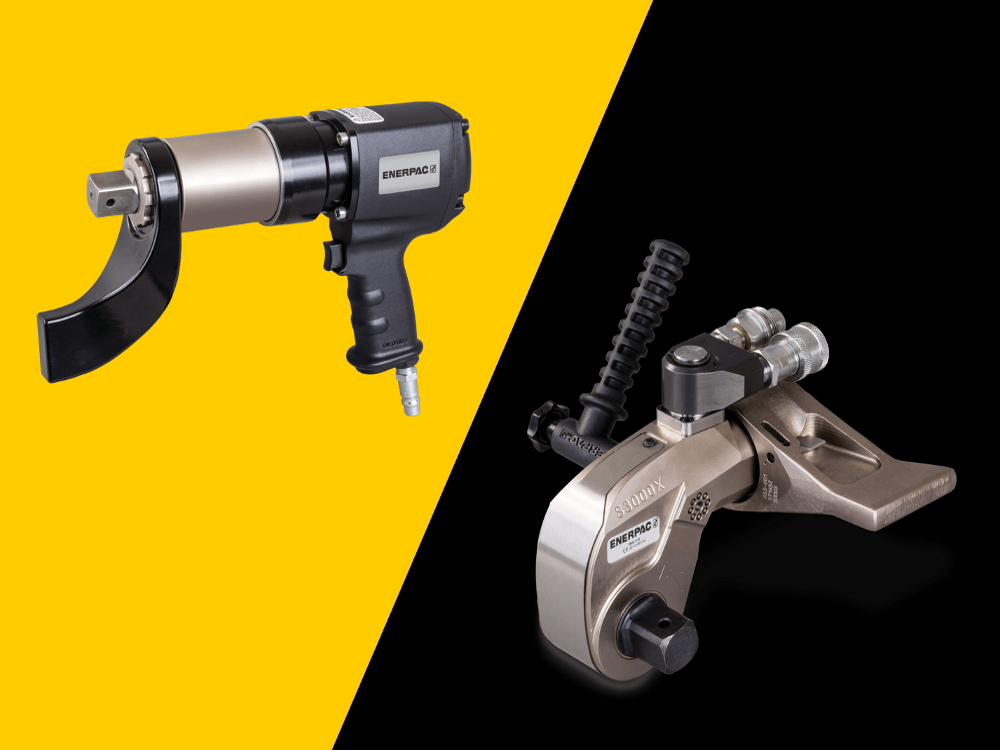

One of the models highly recommended is the BTW-Series Battery Torque Wrench from Enerpac. There’s a choice of five models with torque outputs ranging from 500 to 6,000 Ft.lbs (670-8130 Nm), and square drive sizes of ¾”, 1″, and 1 ½” depending on the model size chosen.

What makes the BTW-Series so accurate?

BTW-Series Battery Torque Wrenches go through the most comprehensive pre-programming and calibration process of any battery torque wrench in the market. With meticulous calibration at 60 distinct points – far beyond the standard 7 points of competing products, BTW-Series Torque Wrenches achieve an impressive +/- 5% accuracy across their entire operational range. Setting the torque couldn’t be easier, and you can even select your setting in Ft.lbs or Nm, no conversion needed.

The other benefits are significant too. The compact, handheld, battery-powered design makes it ideal for scenarios where physical space is limited or where access is challenging. With no cords, pumps, hoses, or trip hazards to worry about, the single-operator usage offers the potential to double the productivity of two-person bolting teams.

View the full range of the BTW-Series and get the specifications.