Self-Propelled Modular Transporters: Applications, Features and Benefits

March 1, 2021

0

Applications for a self-propelled modular transporter

Self-propelled modular transporters (SPMT) are platform vehicles used to move heavy loads on-site – typically during construction and maintenance projects.

The SMPT is especially useful wherever there’s no access for a crane or truck. They allow the load to be moved in multiple directions, and over distances longer than is practical with a hydraulic gantry or skidding system.

Examples of items often moved with a self-propelled modular transporter are listed below.

Generators

Reactors

Generator Turbines

Transformers

Wind Turbine Components

Bridge Modules

SPMTs can be combined with other heavy lifting systems to deliver tailor-made solutions for a wide range of on-plant projects. The animated video below shows how a generator can be moved into position using an SPMT with a hydraulic gantry.

Manoeuvrability of SPMTs

The wheels on a SPMT include their own motor and can therefore be rotated individually. This provides impressive manoeuvrability and control.

In addition to the usual forward and reverse directions, the SPMT can be switched to ‘Crab’ mode, allowing it to move sideways, or to ‘Carousel’ mode, to rotate the whole configuration. The integrated lifting cylinders also make it possible to raise and lower the load – a useful feature that assists with loading and unloading.

Modular Design

SPMT modules can be combined to offer different configurations. Depending upon the model, the Enerpac SPMT can be arranged with up to 6 modules in length, and 2 modules wide. Between One and four “two tier-4” diesel driven hydraulic power packs will be needed to drive the transporter (depending upon the size of the configuration).

How an SPMT is Controlled

A self-propelled modular transporter is controlled using a wireless control system.

For example, the “Intelli-Drive” system used with Enerpac SPMTs allows the operator to control the transporter using a hand-held remote controller.

With so many wheels and configurations, you might expect the controls to be complex. But direction of travel is simple for the operator, who is able to control the SPMT with two joysticks. It also has pre-programmed steering modes, allowing switching from normal steer to ‘crab’ or ‘carousel’ with the push of a button.

The system also recognizes how many modules are joined together and treats them as a single configuration. No need for time-consuming programming before you start the job, and no need to hire a specialized trailer operator.

Distribution of weight is also taken care of through the Intelli-Drive system, which recognizes the position of the weight, and spreads this across the modules and wheels (within a three-point triangle).

The advanced braking system allows careful control of the speed – offering vital reassurance that’s especially important when transporting hazardous waste. All of these features together make the control system intuitive and easy to use. (Arguably no more difficult than operating a fork-lift truck!).

Size and Capacity

Some heavy hauling companies use large SPMTs designed to transport huge loads of 500 tons or more over a wide variety of terrains – including off road surfaces.

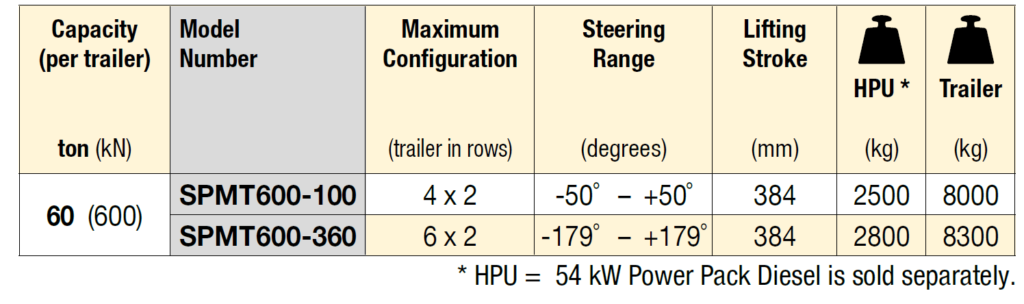

By contrast, Enerpac self-propelled modular transporters offer a nimble solution for smaller ‘on-plant’ transportation challenges. These have the capacity to handle up to 60 tons per trailer, and up to 720 tons in total when using the maximum configuration of 12 trailers. Their minimized height and slim design makes them ideal for in-plant transportation at nuclear and petrochemical plants, and other industrial sites where space is confined. The low-height design is especially useful for positioning the unit under the item for loading and unloading.

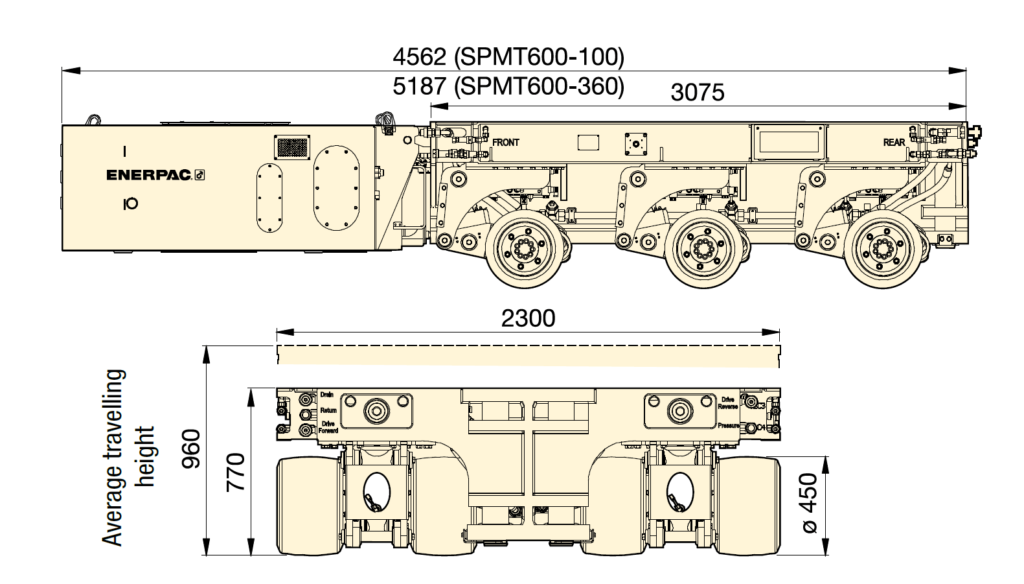

Enerpac SPMT Dimensions and Specifications

From Enerpac, there are two different models available – The SPMT600-100 and the SPMT600-360. Each has different capabilities, such as maximum configuration size and steering abilities. For example, the smaller model does not include the carousel capability, but the 360 offers both crab and carousel and the maximum number of modules.

Get in touch to find out how your plant could benefit from a self-propelled modular transporter