How to Choose the Right Hydraulic Hand Pump

January 26, 2023

0

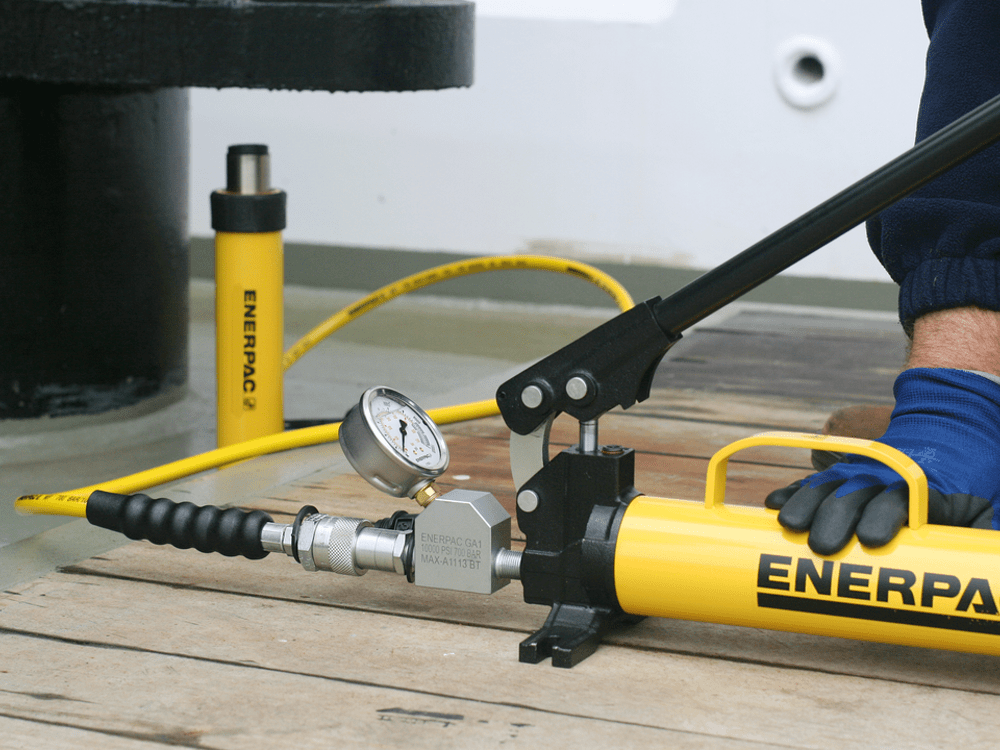

A hydraulic hand pump is a simple, yet essential piece of equipment used in a variety of industries. They are vital for many force applications – especially in construction, manufacturing, and maintenance operations.

However, with so many different models on the market, it can be difficult to know which is best suited to your type of work. This guide will help you understand the different pump types and their features.

Do your Research

Before you go ahead and buy a hydraulic hand pump, it’s important to do your research and understand their differences. With so many to choose from, you will want to compare features and prices. It is also a good idea to assess the quality of the product and if it’s made by a reputable manufacturer.

A hydraulic hand pump does a simple job, which is to deliver pressurized hydraulic flow to a tool and then return it back to the pump reservoir. But that doesn’t mean you should take shortcuts and opt for the first one that appears in your internet search results. There are a few simple but important considerations to take on board that will steer you towards the right product.

Prioritize Quality

When you are choosing a hydraulic hand pump, it is important to prioritize quality over price. A high-quality Enerpac pump will last longer and be more reliable than a cheaper model. You will save money in the long run as you won’t need to replace it for many years.

Single vs 2 Stage Hydraulic Hand Pumps

With each stroke of the handle on a single-speed hydraulic pump, hydraulic oil is drawn from the pump reservoir towards the tool by the same amount. For many applications, this simpler and lower-cost option is fine. But for projects needing greater flow, for example when oil is to be pumped to a large hydraulic cylinder (or multiple cylinders), a single-speed pump can be hard work.

The alternative is a 2 stage hydraulic pump (2 speed), which has the added advantage of delivering high flow at lower working pressures. This gets you faster to the point where the real work begins. It then automatically delivers low flow at high pressure just at the time when you need more control. Compared to a single-speed pump, some two-speed types can reduce the number of handle strokes by as much as 78%! For a more in-depth comparison read our other blog post.

Oil Capacity

Hydraulic hand pumps are available in a wide range of oil capacities. A small model typically has a usable capacity of around 20 in3 (327 cm3), but there are some with as much as 453 in3 (7423 cm3). A larger reservoir will give you more options but will obviously make the pump much heavier, so think about how much oil is really needed for the applications you intend to carry out.

Low vs High Pressure

Most Enerpac Hydraulic Hand Pumps can withstand pressures up to 10,000 psi (700 bar), but this isn’t always necessary. For lower working pressures up to 5,000 psi (350 bar) the P18 is a cost-effective single-speed option. However, if you need a 2 stage hydraulic pump go for the P1425000.

Hydraulic Hand Pump Materials

When it comes to the materials used for the main body of the pump, you have the choice of steel or glass-filled nylon. There’s plenty of configurations available in both types, so it really comes down to your personal preferences, weight, and the working environment. Metal-bodied pumps are the traditional tried and tested option that offer reassurance to many people. However, glass-filled nylon reservoirs are also incredibly durable, and these offer an unrivalled combination of strength, weight, and resistance to corrosion. A glass-filled nylon pump will be a few pounds lighter than steel equivalents.

Hand Pumps for Single-Acting and Double-Acting Hydraulic Cylinders

If you intend to use your pump with hydraulic cylinders, will these be single or double acting?

A double-acting cylinder gives you a faster and more controlled plunger retraction, but you will need a pump designed specifically for this purpose. Take a look at the P842, P84, and P464 models.

Safety Features

Safety should always be the number one concern, so choosing a good quality pump from a reputable manufacturer is an essential first step. Some features and tips relating to safety include;

• Non-conductive fiberglass handle

• Internal pressure relief valves for overload protection

• Lower handle effort of 2-stage pumps

• Handle lock and lightweight construction for easy carrying

• Corrosion-resistant finishes

• Using a pressure gauge as a ‘window’ to what’s going on within the system

• Always follow manufacturer operator instructions

• Consider extra safety tools such as the Hydraulic Coupler Bleed Tool for safe depressurization

• Make sure you keep threads on couplers clean and in good condition.

Extreme Environment Pumps

When working in extreme environments such as the oil & gas, or petrochemical industries, a hydraulic pump may be exposed to corrosive substances and extreme temperatures. For these situations consider pumps with corrosion-resistant materials such as stainless steel, nickel-plated valves and cylinders, anodization, and plastic-encapsulated metals. Viton® Seals will also offer heat and chemical resistance.

Alternatives to Hydraulic Hand Pumps

Foot Pumps

Would a foot pump suit you better? If crouching to activate your hand pump is an issue, or if you want to keep your hands free then a foot pump could be a good alternative option. Look at the P392FP which is a 2 stage foot pump with a robust steel frame.

Hydraulic Foot Pumps

Powered Pumps

For ad-hoc projects, a hand pump is likely to be the right choice. But for frequent and repetitive projects – and especially those with multiple cylinders a powered pump could be much better for you. Plug in electric and compressed air hydraulic pumps are common. For remote locations without mains power or a compressed airline the choices are battery and gasoline-driven pumps.

Battery Driven Hydraulic Pumps

Cylinder and Pump Sets

If your work involves using hydraulic cylinders buying a cylinder and pump set is a quick and easy way to get what you need, without the hassle of buying components separately. A set typically includes a single-acting hydraulic cylinder (aka a jack or ram), a two-speed pump, a 6-foot hose, calibrated gauge, and a gauge adaptor. Cylinder capacities vary from 5 to 100 tons and the pump options include hand or foot-operated models.

Cylinder and Pump sets

Find a Dependable Supplier

Once you have chosen the right hydraulic hand pump, you’ll need to find a reputable supplier.

You can locate your nearest Enerpac distributor on our website. Or if you are based in the United States you can order your pump online directly from Enerpac.

Enerpac Distributors

Conclusion

Most people reading this article will be technical-minded engineers with a clear idea of the intended applications. With these projects in mind and an understanding of the key points we’ve covered above, hopefully, you will be in a good position to select the best hydraulic hand pump for your future projects. Here is a summary of the key considerations:

• Choose a quality product

• Single vs 2 stage pumps

• Oil capacity

• Low vs high pressure

• Materials: Metal vs Reinforced Nylon

• Single or double-acting cylinder compatibility

• Extreme environment pumps

• Consider alternatives