How to Avoid a Cylinder Depressurization Safety Incident

April 19, 2021

0

If you need to disconnect hoses and drain the oil from a hydraulic cylinder how do you know when it’s safe to go ahead? Surely, if the pressure gauge on the pump reads zero this means you’re good to go, right?

Sometimes this might be true. But it’s dangerous to assume this will always be the case. A recent incident we became aware of shows why you need to be cautious.

Hydraulic Cylinder Safety Incident

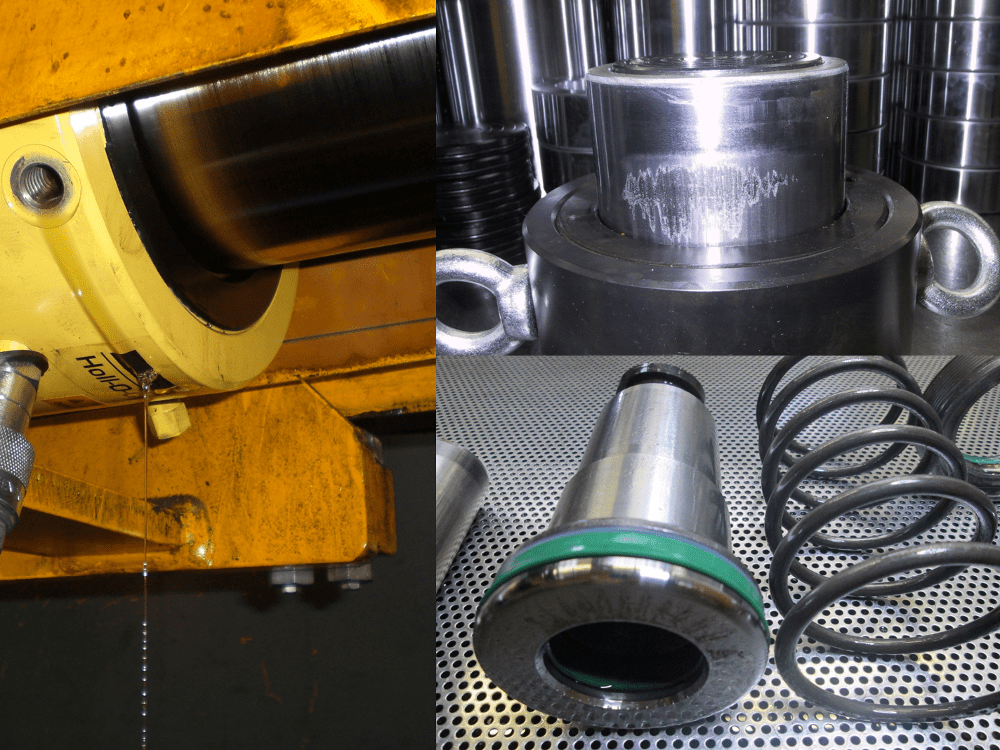

A technician was carrying out a service of a hydraulic cylinder to replace the seals. The cylinder was being pressurized up to 9000psi / 621 bar for testing. The pressure held steady, but when attempting to depressurize the system, the plunger would not retract.

The technician saw that the pump’s pressure gauge read zero. He then disconnected the hose from the pump and connected a coupler to drain the cylinder. Two other technicians joined in to try and troubleshoot the incident. One used a wrench to disconnect the fitting, and the other to hold a bucket in front of the cylinder hoping to catch the oil.

At first, they saw some drops of oil coming out of the cylinder, and at this point assumed the cylinder was not pressurized. On the last thread of the coupler the fitting shot out rapidly, hitting the bucket, and two technicians were knocked to the floor covered in oil. Fortunately, there were no serious injuries.

Why do incidents like this happen?

If hoses aren’t connected correctly, or if a coupler is defective, it is possible for pressure to enter the cylinder, but then be unable to exit when the pump pressure is released. (If the pressure remains blocked in the cylinder the pressure gauge will show zero).

What should have happened?

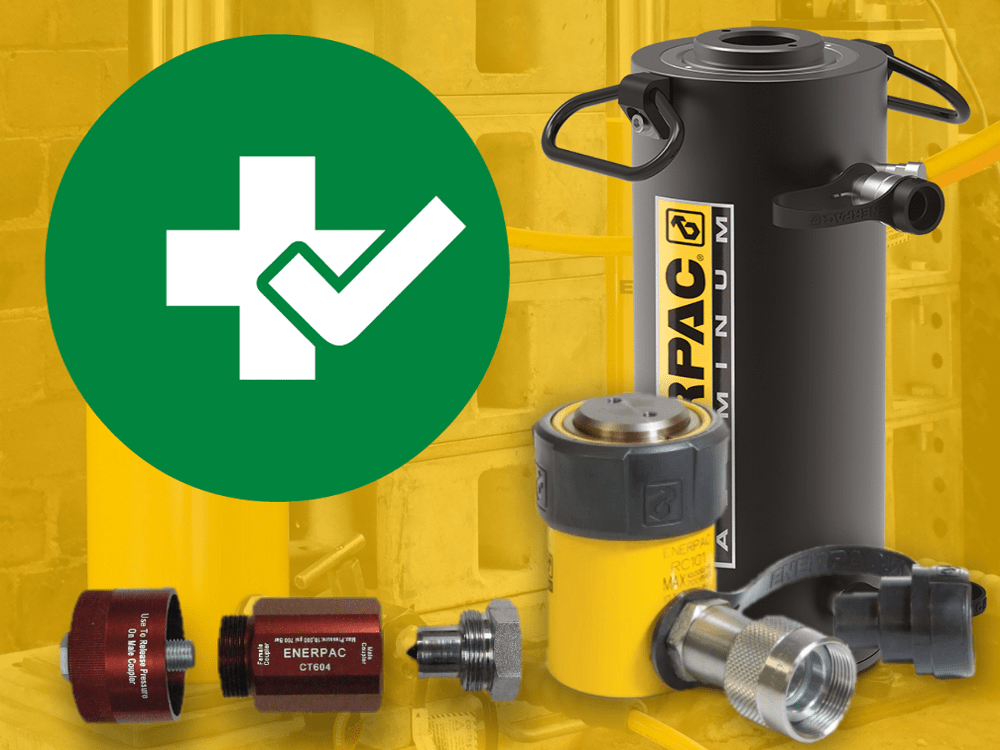

Seeing that the plunger was stuck in the extended position was a clear sign that the cylinder may be still pressurized. Attaching an Enerpac CT604 Bleed Tool to the coupler would have allowed safe depressurization and make the plunger retract.

Hydraulic Coupler Bleed Tool

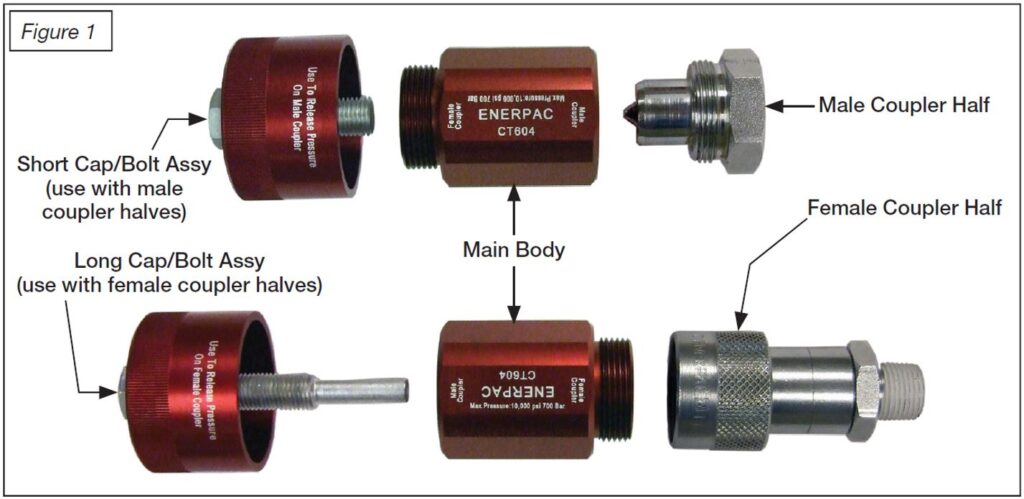

A bleed tool like the Enerpac CT-604 can be used on Enerpac style CR400 and CH604 couplers to depressurize hoses and cylinders. Using simple accessories like these is a great way to minimize the threat of injury from projectile parts and under-skin hydraulic fluid injections.

The CT-604 is compatible with C Series couplers and works by slow hand rotation of the knob. This applies a force onto the ball or cone inside the coupler. Once the ball or cone is pushed from its seat the pressure is relieved. If the object is under high pressure, hand force might not be enough to open the coupler. A properly sized spanner can be used on the hexagon bolt head to turn and push the ball or cone from its seat.

How to Choose the Right Cylinder

Important Safety Points

- If the hydraulic device is supporting a load, block and crib the load as required, so that the load will not shift or drop when hydraulic pressure is relieved.

- Check that the threads on the coupler half to be depressurized are clean and in good condition. Do not attempt to bleed a coupler if threads are damaged.

- Check that all threads on the bleed tool main body and cap/bolt assemblies are clean and in good condition. Do not use bleed tool if threads are damaged.

- Hand tighten the bleed tool main body only.

- Never attempt to repair or reuse a worn or damaged coupler.

Find out more about the CT-604 Coupler Bleed Tool.