Hydraulic Cylinder Repair

January 25, 2021

0

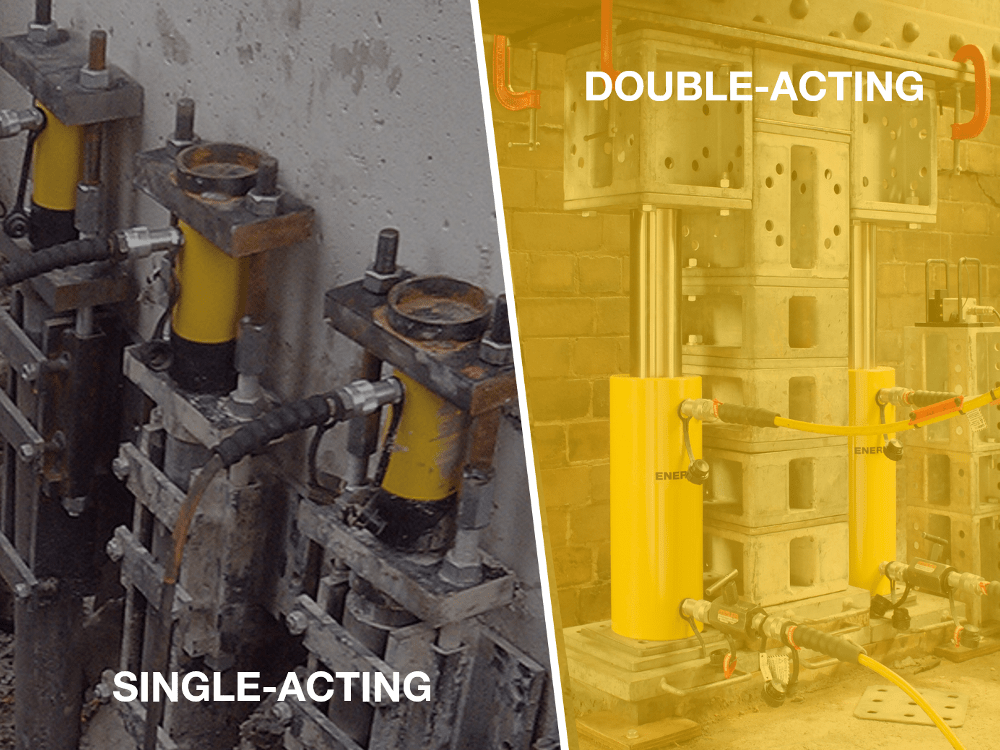

Hydraulic cylinder repair is not something you should try yourself. The consequences of a badly managed repair job could be severe. Not only could the cylinder fail during use, there is also the very real risk of serious injury during disassembly.

For example: when trying to open a single-acting hollow cylinder, the force of the compressed spring could fire the stop-ring into your face, with a potentially severe or even fatal result! That’s why it’s best to use an Authorized Enerpac Service Center.

Manufacturers go to great lengths to ensure their cylinders are robust and fit for purpose. For example, at Enerpac, before we release a new cylinder, we test our designs in a variety of standardized methods to mimic many of the common applications. We also perform extensive overpressure and sideload tests.

So, despite all this, why do hydraulic cylinders need to be repaired?

The Need for Hydraulic Cylinder Repair: Causes of cylinder wear and damage

The most common reason why hydraulic lifting cylinders get damaged is incorrect use through lack of knowledge of the operators.

Sideload

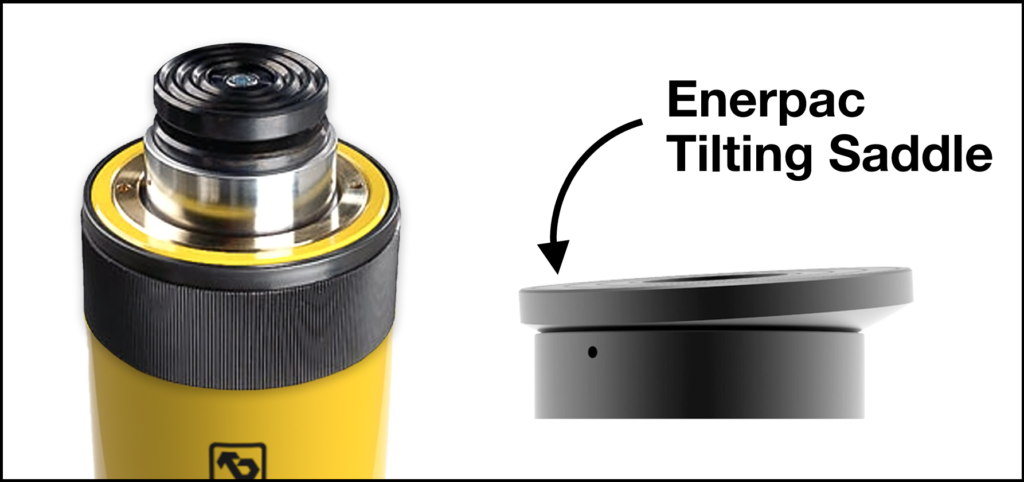

Sideload is the biggest enemy of a cylinder, and it is quite common for the operator to be unaware of the existence of sideload in the application.

Most of the time, the problem is inadequate contact between the saddle and the load. Using a tilting saddle helps improve this contact, extending cylinder life. In multiple point lifts, side loads can be induced by the hyperstatic nature of the lift.

Oil Contamination

This is another common cause of cylinder damage. Keeping the connections clean is a must. Couplers need to be kept spotlessly clean before connecting, to avoid getting debris in the hydraulic circuit. Doing this will extend the life of the pump and cylinder. Find out how to choose the right hydraulic oil.

Overload

Another common cause of damage. Enerpac pumps are limited to 700 bar working pressure (10,000 psi), so a cylinder cannot be overloaded when lifting.

However, when lowering the load using several cylinders, uncontrolled movements can occur through valves opening and closing.

This results in the whole load resting on top of too few cylinders – therefore overloading them.

This problem can be avoided using Enerpac Controlled Lifting Pumps, and especially our EVO systems. These provide full control on multi-point lifting projects, therefore reducing risk.

What are the signs hydraulic cylinder repair is needed?

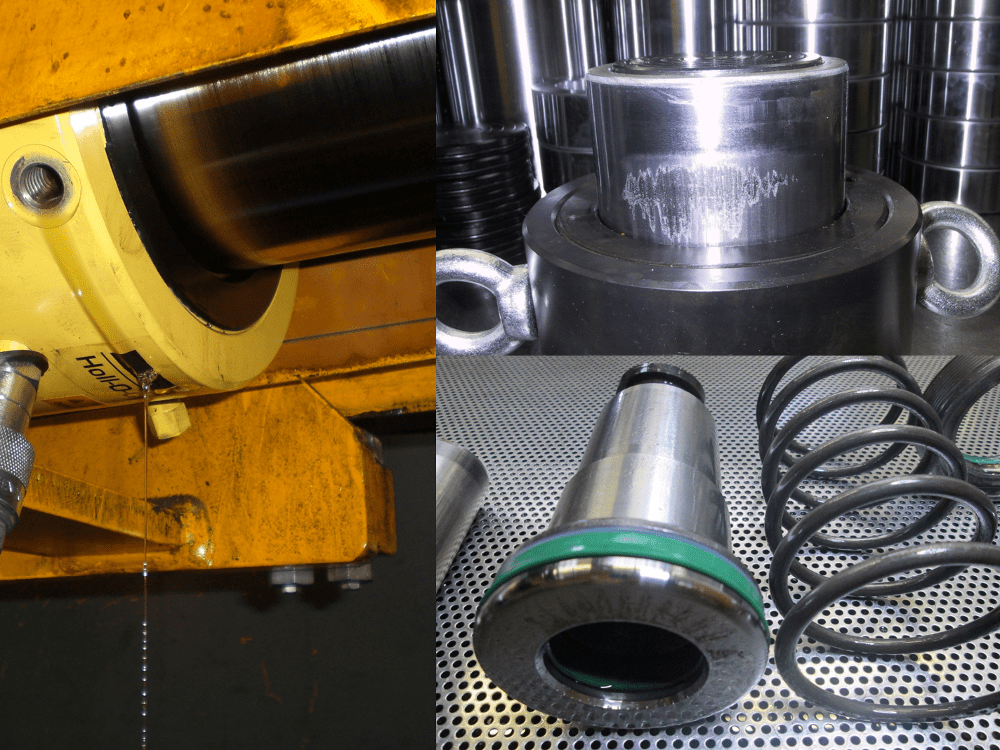

Most frequently, oil leakage is the first sign that a repair should be carried out. Before that happens, if we notice the oil in our system or in our pump is not clean, taking preventive maintenance and changing this will avoid damage.

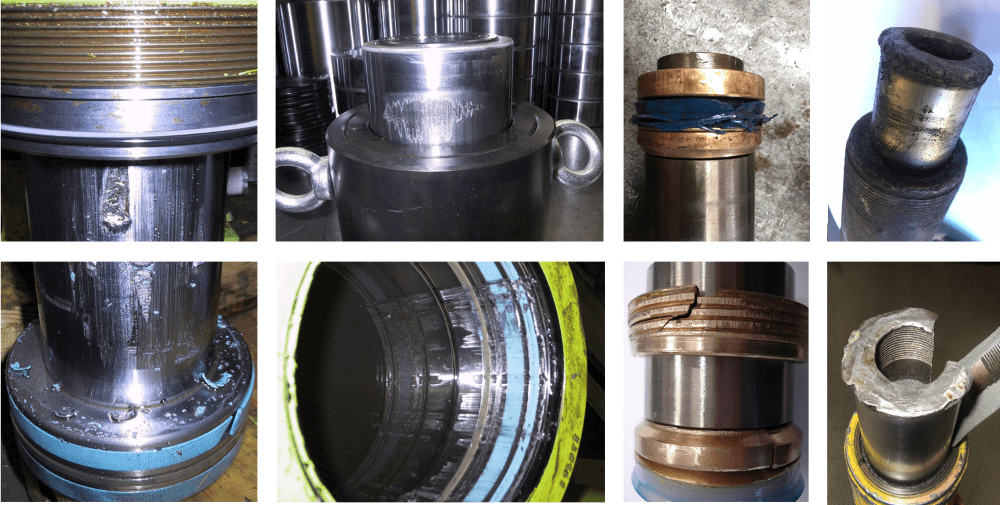

Hydraulic Cylinder Repair: The Types of Cylinder Damage

Seal Wear

This is solved by installing a new repair kit. Once the cylinder is disassembled, we recommend replacing all of the seals.

Scores and Scratches

This kind of damage can be seen in the cylinder bore or on the plunger rod. Causes include sideload or dirty oil.

Base Deformation

A cylinder base can be deformed, inflated, and can even burst due to overload. That’s why it is important to follow an 80% rule: always keeping the cylinder within 80% of its rated capacity and stroke.

Plunger Mushrooming

Sometimes an operator will remove the standard saddle (which is hardened). This may be because the cylinder with the saddle doesn’t fit easily into a tight space. The outcome is that the load is placed directly onto the plunger.

With mushrooming, the plunger cannot retract completely, and it will need to be machined in order to dismantle it. Usually, as there has been permanent deformation, these cannot be repaired.

Which cylinder components can be replaced?

In principle, most components of a cylinder can be replaced. But in practice, the usual items include seals, wear bands, and (depending on the case), even the plunger and stop ring. The cylinder base cannot be replaced for reasons explained later.

Cost of repair vs buying a replacement

Whether you choose to repair or replace a hydraulic cylinder will depend upon the severity of the damage. Before a repair can start, you should be aware that Enerpac will not supply new cylinder bases for a repair for 2 reasons:

- The cylinder loses traceability because cylinder markings are no longer present.

- The cylinder base is the most expensive part. You also need to add the cost of components such as a seal kit, plus other damaged parts, and labor cost.

When you add up all these costs, you will probably end up with a non-economical repair as compared to the cost of a new cylinder.

Hydraulic Cylinder Repair: Where should you go?

If you have a problem with your cylinder you should always contact your nearest Authorized Enerpac Service Center. Here, they will have staff trained by Enerpac who can do a thorough analysis and repair, and also provide a warranty.

An Enerpac Authorized Service Center will always provide the best options – whether this is repair or replacement of the defective product.

In many areas, the Authorized Service Center will be able to help you with regular preventive maintenance on your fleet of cylinders under the Enerpac Maintenance Program (EMP).

Find contact details for you your nearest Authorized Service Center on the Enerpac website

You may also be interested to see our Enerpac Safety Video on YouTube