When Should You Replace Hydraulic Oil?

June 13, 2022

0

Over time and through repeated use, the hydraulic oil in your tools will degrade and become less effective. This is a normal process and happens for a few reasons.

The higher the pressure in a hydraulic system the more the oil will compress and degrade. But arguably, the most common reason is because of contamination. If you ignore the warning signs and do not replace the hydraulic oil the performance of your equipment may be affected, and the oil will lose its ability to defend against friction and corrosion.

Types of Hydraulic Oil Contamination

Water

Water enters the hydraulic system either through carelessness when handling the oil, via damaged seals, or by condensation. As you will be aware, oil and water don’t mix – and within a pressurized hydraulic system together they cause foaming and cavitation. The water will also result in clogged filters, reduced lubrication, and corrosion.

Aeration

Aeration occurs when air gets into the system through seals and fittings, or maintenance. The air trapped inside the system can lead to cavitation causing a spongy or slow hydraulic response. Hydraulics depend on the fact that fluids can’t be compressed, and a system that contains air is more elastic. Furthermore, any resulting oxidation from the air can increase viscosity, create sludge, deplete additives, and increase the acidity of the oil.

Other Causes of Oil Degradation

Cavitation

Cavitation is when vapor bubbles are produced as a result of a rapid change in fluid pressure. These bubbles then collapse and cause small vibrations and shock waves. If this happens repeatedly, metal parts in the system may be damaged.

Overheating

When hydraulic oil becomes overheated it increases oxidation. Causes of overheating include restricted flow or excessive flow.

How to Tell it’s Time to Change Hydraulic Oil

What color should the oil be?

If you’re using an Enerpac hand pump with the correct grade of oil this is likely to be an amber color. The grade of Enerpac oil used with powered hydraulic pumps is more viscous and can be identified by blue color.

What are the warning signs it’s time to replace hydraulic oil?

• When the oil is dirty, sludgy, and has darkened.

• If you find residue in the reservoir.

• When the oil is foamy – (contaminated with air).

• If it is milky – (contaminated with water).

How to extend the life of your hydraulic oil

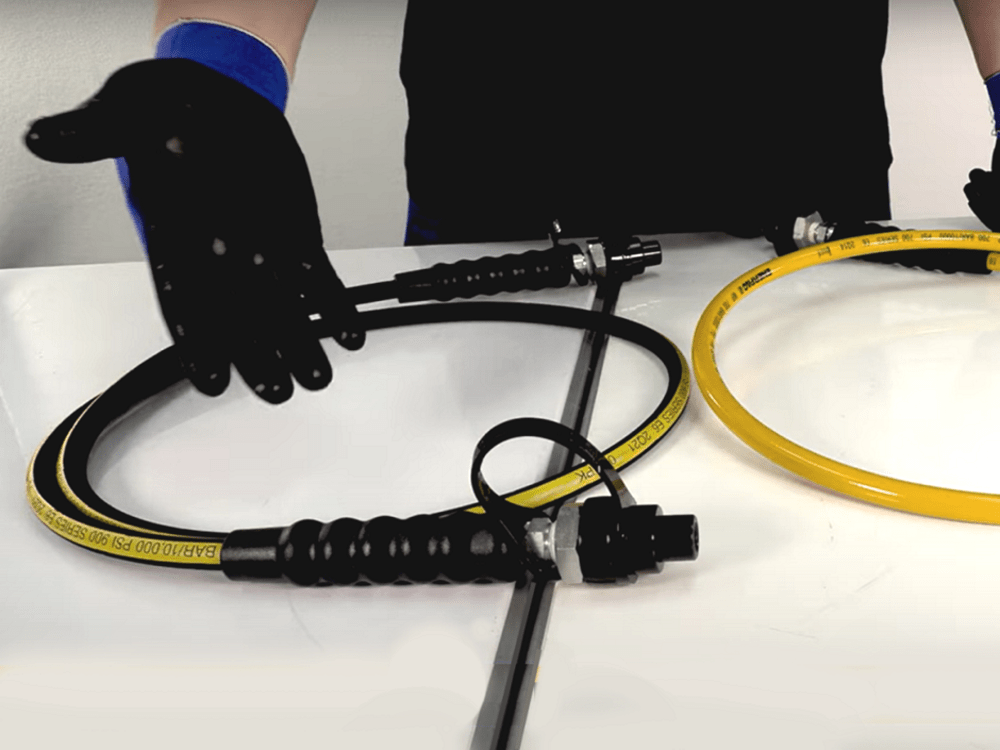

• The best way to extend the life of hydraulic oil is to minimize contamination. You can do this by working clean and taking extra care whenever you set up and connect your system. Before connecting your hydraulic hoses, make sure you remove any dirt and moisture from the connectors and other components.

• Place an oil filter in your system. Examples are the PF-25 replacement filter kit and the ZPF Return Line Filter