Innovative Railroad Solutions: Simplifying Complex Track Lifts with the TL248 System

August 6, 2024

0

Lifting tracks is one of the most important aspects of railroad maintenance. Whether you are replacing railroad ties, renewing diamonds and retarders, or relaying aged track, lifting existing infrastructure is critical.

When dealing with straight sections of track, railroad maintenance is relatively straightforward, particularly in easily accessed areas. But projects become increasingly difficult and costly when dealing with complex track sections like junctions and crossings.

Common issues include:

Downtime – The longer a lifting project takes to complete, the longer the curfew required. And the longer a section of track is out of commission, the more money operators lose through reduced or curtailed operations. To make matters worse, the penalties for overrunning curfews (track possessions) can be very severe.

Access – Complex track sections are not always easily accessible by traditional cranes and side booms. Carrying out railway track maintenance near overhead wires, tunnels, and bridges is a logistical headache. These factors also lead to increased risk and safety concerns.

Resources – Traditional track lifting exercises can require as many as 12 people when dealing with complex sections. Combining the cost of curfews and personnel adds significantly to the overall project cost.

Inaccuracies – The precision offered by cranes and booms varies – depending on the operator. But when complex track sections require high precision for safe operations, inaccurate positioning is risky, the TL248 helps to alleviate those risks.

Simplifying complex lifts will help to address these issues, but doing so will require revolutionary new railroad maintenance equipment such as the Enerpac TL248.

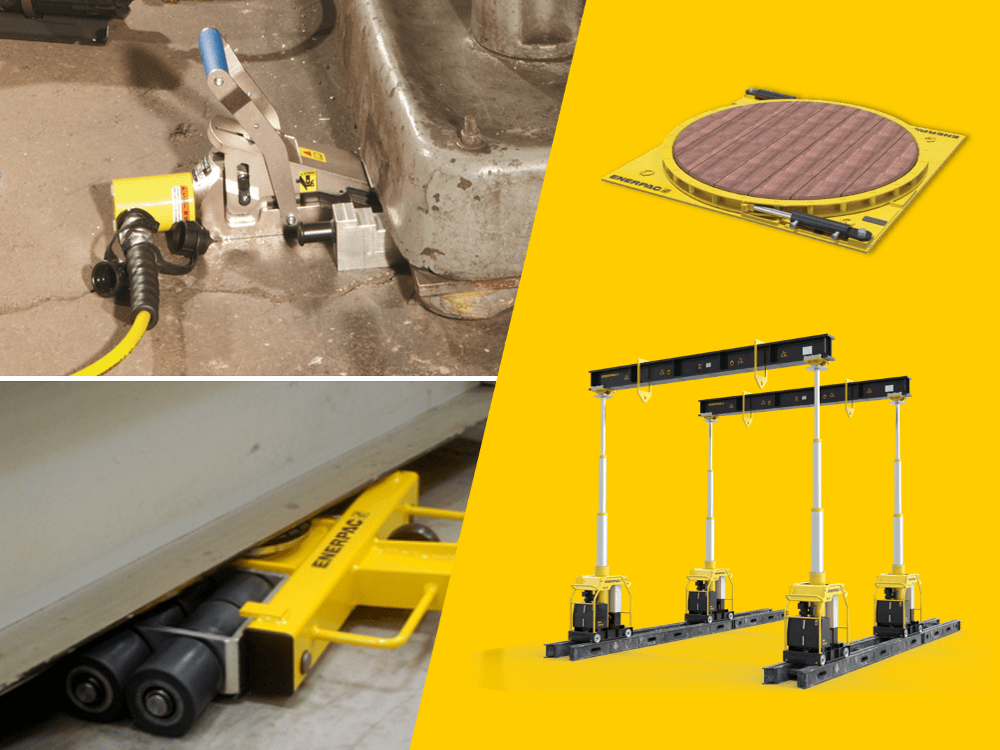

Introducing the TL248 Track Lift System

The alternative to traditional methods is to perform complex track lifts from below the rail. Using this technique, it is possible to complete railroad maintenance on junctions, crossings and switches more easily and quickly than ever before.

The Enerpac TL248 Track Lift System uses four framed 62-ton (550 kN) hydraulic cylinders to lift railroad track from the track bed directly.

But why is this new design so revolutionary?

Accelerating railway track maintenance projects

TL248 hydraulic cylinders can be deployed in situ without much of the disruption associated with traditional lifting systems. This means that projects can be started – and finished – more quickly, helping to reduce curfew timeframes.

Speed of deployment and ease of use allow track maintenance teams to complete more projects each day. In the United States, Class I Railroad feedback revealed that a team of four engineers could complete up to four diamond crossings or six switches per day.

This is a product that has been developed and refined in real-world scenarios with feedback from real-world railroad maintenance teams.

Delivering significant cost savings

The faster you can complete railway track maintenance projects, the less they cost. The Enerpac TL248 not only helps your teams be more productive, but it also reduces ‘dig-out time’ and the amount of people required for even the most complex lifting projects.

Unlike many traditional lifting solutions, the TL248 generates ROI extremely quickly. The TL248 pays for itself in as few as 10 complex lifts.

Combines speed and precision

Just because the TL248 is faster than other solutions does not mean that you have to sacrifice accuracy. Each of the four hydraulic cylinders offers complete control and accuracy to within 1/8 inch (3.2mm). Quite impressive when you consider the Enerpac TL248 offers a total lift and hold capacity of 248 tons.

This high degree of accuracy means you can rely on the system for complex lifting projects like replacing turnouts, diamond crossings, switches, retarders, and bridge ends.

A highly portable lifting solution

Complex lifting projects are often further complicated by height restrictions or accessibility issues. Normally, the solution is to use track-mounted railroad maintenance equipment – but this can create additional obstacles during the project.

The TL248 unit has been designed to go anywhere. Weighing 1660 lbs (753 kg), the unit is compact and portable, easily transported on a flatbed truck. Fitted with a pair of lifting points, along with fork pocket access, loading and unloading the TL248 is quick and easy, allowing your engineering teams to get to work faster.

And because portability often increases risk of theft, the TL248 has some useful anti-theft features. Locking tool storage protects your assets against being stolen, wherever the unit is located. And a locking battery disconnect prevents unauthorized use of the system. Even the on-board battery is protected by a lock so it cannot be tampered with or stolen.

Simplicity as standard

When your engineers arrive on site, they do not want to waste time preparing complex railroad maintenance equipment. The TL248 is not only portable, but also incredibly simple and fast to set up. Deployment can be completed in a matter of minutes, using color-coordinated hydraulic lines and valves to avoid mistakes while setting up.

This simplicity extends to the physical design of the unit too. By reducing the number of moving parts, Enerpac has created a system that is less prone to failure and is easy to service and maintain. Your railroad maintenance crews can rely on Enerpac equipment for the most complex lifting tasks.

Safety first

Increased deployment speed does not come at the cost of safety. Careful color coding and labeling ensures that your railroad maintenance crews have everything they need to deploy the unit properly. A full operators manual is supplied and Enerpac can offer full familiarization training on-site by one of our Rail Experts.

The TL248 is also fitted with LED lighting for equipment operation in low-light conditions. Your team can see exactly what they are doing, even when completing complex lifting projects in tunnels – or at night.

Also, each of the four hydraulic cylinders is supplied with a ballast shield. These shields protect the cylinders against damage from falling debris during operation.

Find out more

You can find the full TL248 Track Lift System specifications here. And don’t forget to check out the rest of the Enerpac railroad maintenance equipment portfolio for even more efficiency gains.