Chain Cutters: How to Cut Chain Safely

December 9, 2020

0

It’s good to know your chain is tough enough not to let you down, but what can you use if you need to cut through a link? A chain cutter or using another method?

The first metal chains are thought to date back to as early as 225 BC as a means to raise a bucket of water from a well. Chain manufacture has come on a long way since then, with chains now manufactured in high-performance grades of steel.

Today, chains come in various categories ranging from grades 30 through to 120. Grade 30 is made from low-strength carbon steel. This is typically used for securing loads and other general-purpose applications. Logging and towing chains require grade 43 carbon steel, and overhead lifting needs grade 80 alloy steel and upwards.

Let’s have a look at the types of chain cutter and weigh up the options.

Torching

Torching is one of the most common methods. But despite being a cheap option it has its drawbacks. Conveniently, you may already have a blowtorch in your workshop, but there are risks. Not just the potential blowback from a flame to the operator, but also the risk of damaging adjacent links. Any damage and weakening can have catastrophic consequences if the chain fails during use. There’s also the disadvantage that using a torch can be laborious and time-consuming.

Angle Grinders and Cut Off Tools

Again, these tools are commonly found in many workshops. Products like these will eventually cut through the chain, (provided you have enough patience and can live with the safety risks!)

Cut-off tools are similar. They usually work with a 3” disc and are compact and lightweight enough to use with one hand. This makes them a good choice for small metal cutting jobs and working in tight spaces.

Angle grinders are larger and can be used with discs of up to 9” diameter. Provided the motor is powerful enough, they’re certainly capable of tackling heavy-duty cutting jobs, such as metal chain.

As with torching, using an angle grinder or cut-off tool takes time and involves risk to the operator. Two hands are needed, sparks are created, and there’s also the real possibility of the cutting wheel disintegrating when in use.

Mechanical Bolt Cutters

Good old-fashioned manual bolt cutters offer a simple solution. They involve far less risk of personal injury than torching or angle grinders. They are low cost, easy to use, but are only effective on low-grade chains, and small diameters up to 11mm.

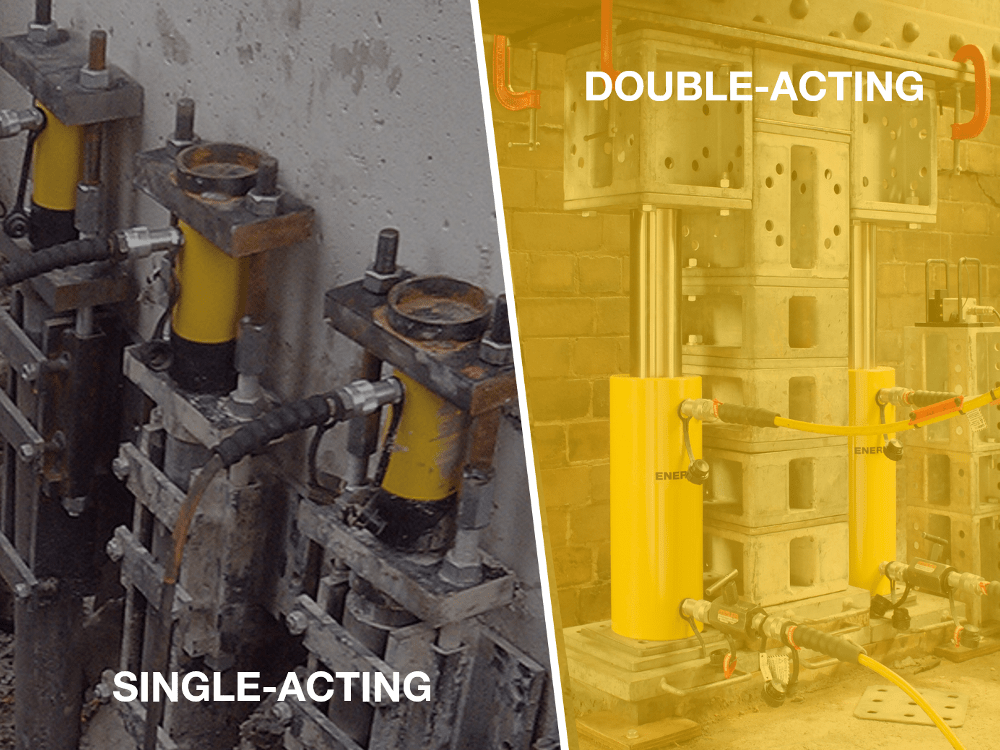

Hydraulic Chain Cutter Machines

Hydraulic chain cutter machines like you see used in a hardware store are commonly limited to smaller chains (10 mm diameter). They are hand-pumped and are designed for low-duty applications, including retail stores and small workshops. If all you need to do is cut through small diameter chains frequently, these offer a simple effective solution

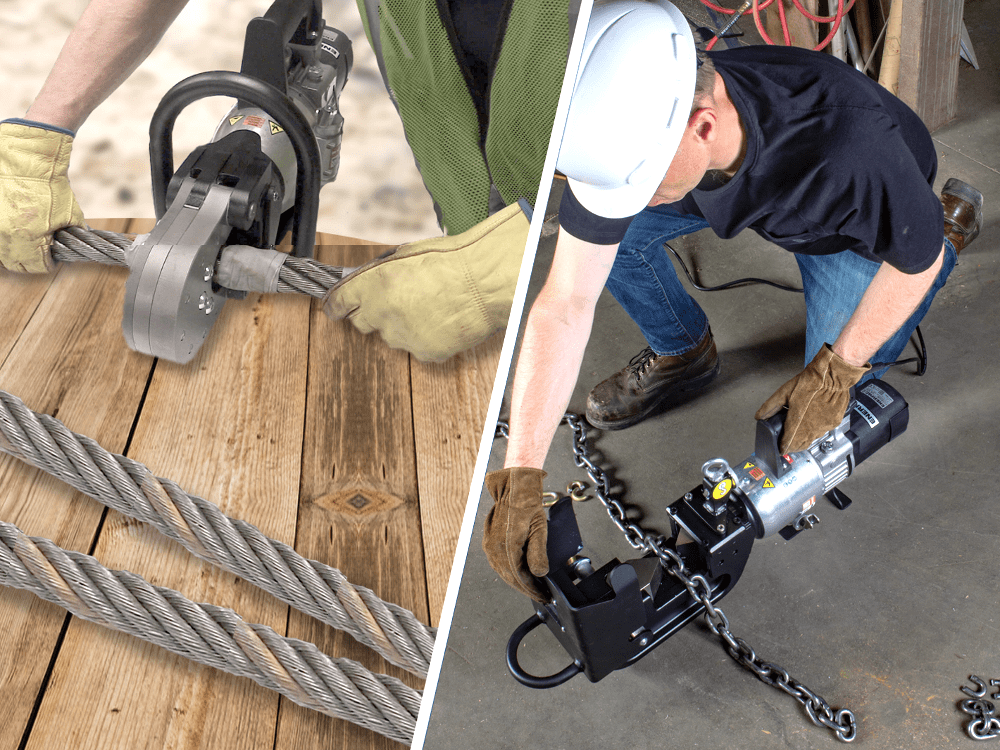

Enerpac Electric Chain Cutters – For safer and efficient cutting of heavy-duty chain

Do you plan to cut heavy-duty chains regularly? The new cutters from Enerpac beat the other methods hands down!

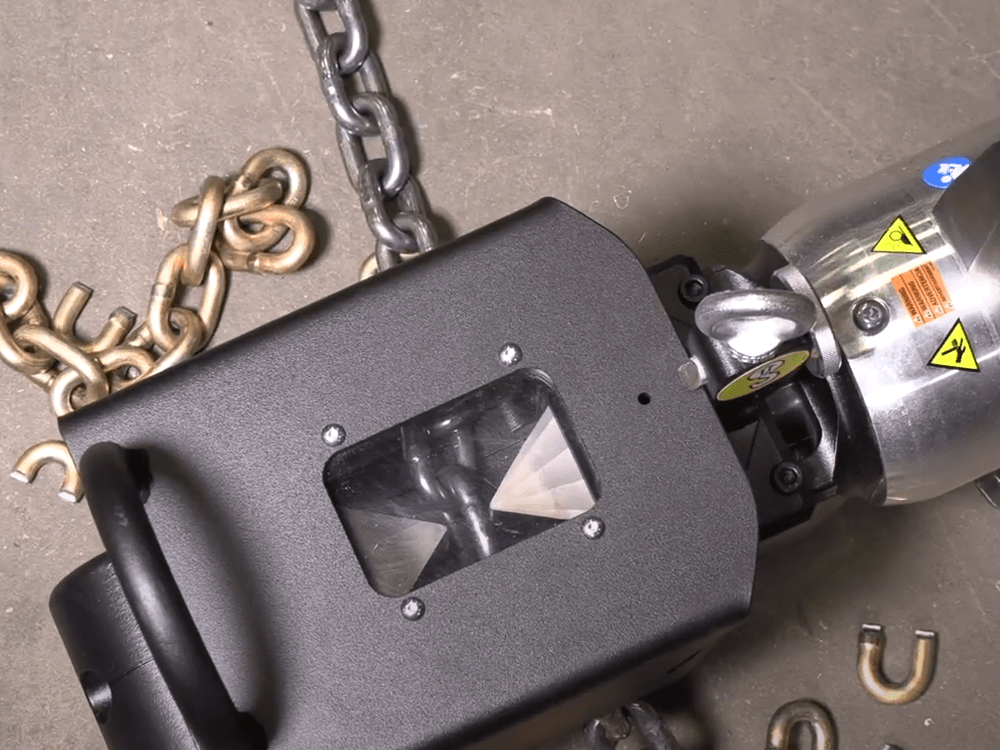

Buy one of these tools and you’ll recoup the investment by working faster, safer, and more precisely. Unlike torching and angle grinders, there’s no need for specialized PPE such as flame-retardant clothing or respirators. This is because the cutting action takes place behind a transparent and protective shield.

Take a look at our video to see the chain cutting tools compared.

How the Electric Chain Cutter Works

Enerpac Chain Cutters quickly drive through the chain link while the transparent shield contains any debris. The electric-powered hydraulic cutter has angled blades that allow for precise cutting of chain links without damaging those which are adjacent.

Enerpac Chain Cutters are fast and cut chain sizes up to 1 1/4” in 35 seconds. As for smaller chains, a 5/8” link will be severed in just 6 seconds.

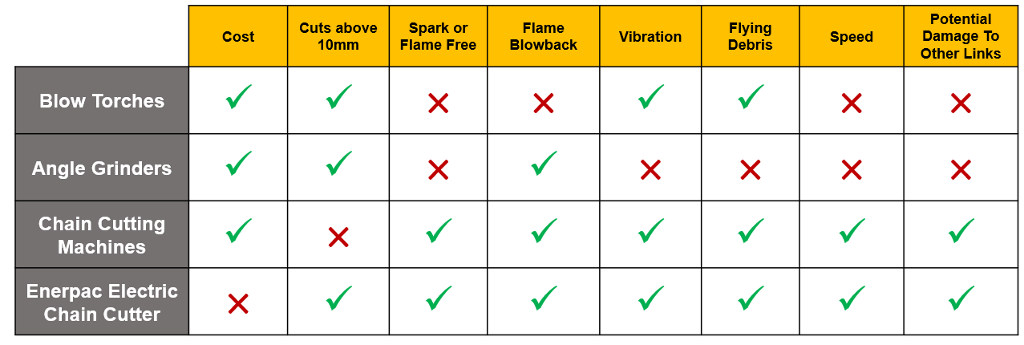

Chain Cutting Methods Compared

The chart below shows the pros and cons of each cutting tool. Choose carefully and get in touch if you need guidance.

Summary

By now you will have seen that your preference for a chain cutting tool depends upon the answers to these questions.

• How often you want to cut chain?

• What is the size and grade of the chain?

• How efficient you want to be?

• Your attitude towards safety