How It Works: The Enerpac 100 Ton 3-Jaw Hydraulic Puller

February 17, 2025

0

Maintaining and servicing heavy machinery requires precision and power, especially when removing tightly fitted shaft-mounted components.

In the rail industry, hydraulic pullers can be used for safely removing shaft-mounted components from rolling stock – including locomotive wheels. For mining maintenance applications, hydraulic pullers can be used on mining equipment – from massive vehicle transmissions to conveyor systems and crushing equipment.

This blog explains how the Enerpac LGH3100 Hydraulic Puller works, its key components, and why it’s a must-have tool for increasing efficiency and safety in heavy industries.

What Is a Hydraulic Puller?

A hydraulic grip puller is a specialized tool designed to remove large, heavy shaft-mounted components without causing damage. Unlike mechanical pullers that require excessive manual effort, hydraulic pullers generate high pulling force with minimal operator strain, ensuring smooth and controlled removal of tightly fitted parts.

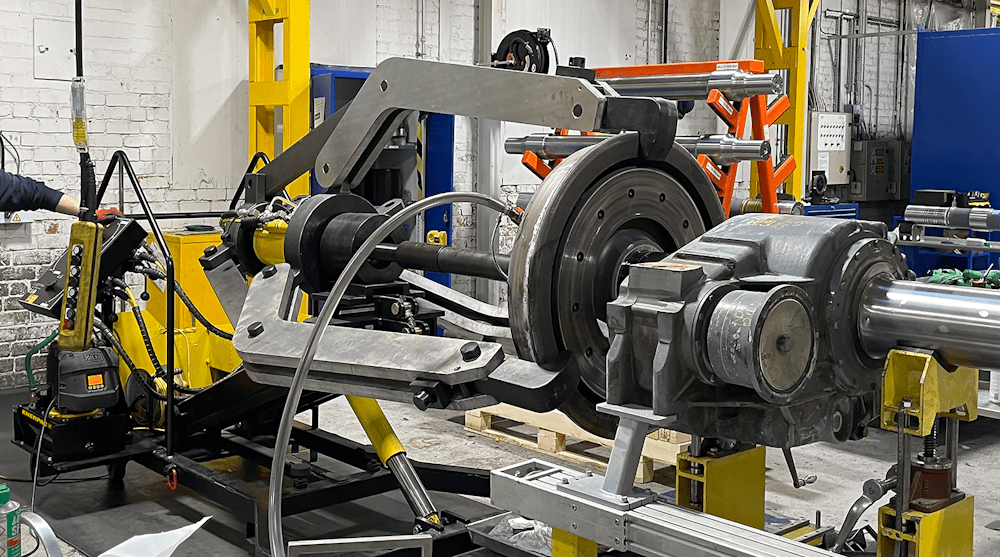

The Enerpac LGH3100 is a cart-mounted, high-force puller with a 100-ton capacity, making it ideal for industrial applications. Its self-centering “Lock-Grip” system ensures that all jaws move simultaneously, allowing for easy mounting and operation by a single operator.

It can be configured to operate in its standard 3-jaw configuration, or a 2-jaw setup for applications where access to the part is restricted.

How the Enerpac 100-Ton Puller Works

Setup & Positioning

- The puller is already mounted onto its purpose-designed wheeled cart, allowing easy transport to the work area.

- It includes a scissor lift, incorporating a hydraulic cylinder, enabling simple height adjustments without the need for lifting equipment.

- The jaws can be adjusted and configured for either a 3-jaw or 2-jaw setup, depending on the application, making it an incredibly versatile piece of equipment.

- The spindle is set to align with the shaft for controlled pulling action.

Easy Control System

The Enerpac Hydraulic Grip is operated using a control panel with three levers and a pendant button.

Lever 1 – Jaws Open/Close

- Move up to open the jaws.

- Move down to close them around the component.

Lever 2 – Apply Pulling Force

- Move up to retract the spindle.

- Move down to push forward and remove the component.

Lever 3 – Adjust Puller Height

- Move up to lift the puller.

- Move down to lower it.

Pendant Button: Once a lever is set in the required position, the pendant controller allows activation movement safely away from the unit by pressing and holding the pendant button. It is released to stop the movement.

Securing the Component for Removal

- The jaws are closed around the component using Lever 1 and the pendant button.

- The lever is returned to its neutral position to lock the jaws before applying pulling force.

- The spindle is positioned correctly using Lever 2, ensuring proper alignment before pulling.

Hydraulic Force Application & Component Removal

- The operator gradually increases force by using Lever 2 (Pushing Cylinder Advance) and the pendant button.

- Hydraulic pressure builds up, exerting strong and uniform pulling force.

- The component slowly slides off the shaft, preventing sudden movements or damage. If necessary, a hoist supports the component as it detaches.

Post-Operation & Maintenance

- The cart is lowered, and the puller is moved to a safe position using Lever 3 and the pendant button.

- Hydraulic pressure is released, and the system is disconnected from power.

- Hoses and hydraulic components are inspected for leaks or wear, ensuring the tool remains in peak condition for future use.

Key Features & Benefits of the LGH3100 Hydraulic Puller

- Single-Operator Efficiency: Synchronized grip jaws and intuitive controls make operation smooth and effortless.

- Ergonomic & Mobile: Mounted on a rolling cart with large industrial castor wheels and forklift pockets for easy transport. Safer Operation: Eliminates torch cutting, hammering, and off-center pulling, reducing workplace hazards.

- Adjustable & Versatile: Hydraulic scissor lift enables center height adjustment from 699 – 1679 mm (27.5 to 66.1 inches).

- Cost-Effective Design: Convertible 2-jaw/3-jaw setup means one tool handles multiple applications.

- Reliable Power: ZE3-Series electric two-stage pump and remote pendant provide smooth and controlled pulling.