Rising to the Rolling Stock Maintenance Challenge With Portable Jacks

October 7, 2024

1

Rolling stock maintenance can sometimes be an operational headache. Aside from the technical challenges of each maintenance task, rail cars or rail wagons must be serviced quickly and efficiently to reduce outages and contain costs.

However, many of the technical complexities come directly from the approach taken. When an asset, such as a railcar or rail wagon, needs to be lifted, carmen or wagon fitters may instinctively arrange for the rolling stock to be returned to the shop where a permanent fixed system will do the necessary lifting.

That sounds simple in concept, but transporting faulty rolling stock back to the shop may be harder than it sounds. Even simple maintenance tasks can be difficult to complete on schedule when access to lifting resources is constrained by physical location.

Solving these access and usage challenges adds time and cost to every rolling stock maintenance project. This is far from ideal when working to a tight schedule.

What’s the answer?

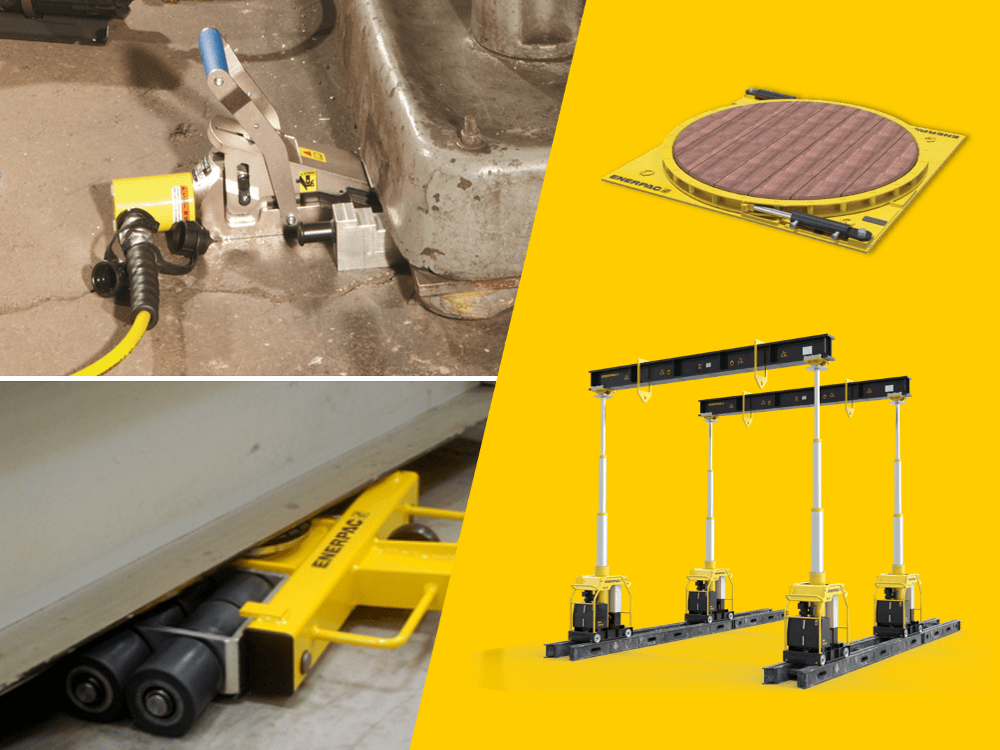

The alternative is to approach each lifting project using portable jacks which means you can raise rolling stock in situ, virtually anywhere on your network, and because the railcar is lifted from below, overhead clearance issues can be minimized.

The physical footprint of your working area is kept to a minimum because you do not need much clearance either above, or around, the rolling stock. Portable jacks can be easily transported – some by hand if required – and used in almost any location, so your teams can work faster and smarter. And with additional accessories, jacks can be locked in place to keep the lifted asset steady, or easily rotated to allow maintenance work to be undertaken from below.

How the Enerpac Pow’R-Riser family can help

Realizing that the portable options to tackle lifting problems on railroads were limited, Enerpac designed the Pow’R-Riser family of portable jacks. A collection of sturdy, powerful and reliable lifting devices that help solve many of your railroad lifting challenges.

Immense lifting potential

Rolling stock is heavy, so you need a jack that offers significant lifting potential. The Enerpac Pow’R-Riser family delivers up to 200 tons lifting capacity. The Pow’R-Riser jack can then be locked in place with its U-Rings and used as a jack stand while your carmen and wagon fitters work.

Fully portable

With two wheels and 4-inch ground clearance, every Pow’R-Riser jack can be wheeled into place by hand. Large, all-terrain tires mean that the jacks can be transported almost anywhere, inside a workshop or out on site. This allows Pow’R-Riser jacks to be used for a range of rolling stock maintenance applications.

Pow’R-Riser jacks are also compact, some just 56 inches tall, including the pull handle. Easily loaded on the back of a truck, this truly is a go-anywhere lifting solution.

Reducing maintenance costs

The Pow’R-Riser family offers potentially significant cost savings in several ways. These portable jacks have lower purchase, operating and maintenance costs than a fixed equivalent. Installing a new fixed system requires a complete rebuild / tear-up of the working area. With a Pow’R-Riser jack, you can begin lifting rail cars and railwagons immediately, allowing you to begin (and complete) maintenance faster. This increases the number of potential use cases for a Pow’R-Riser jack. Smaller, irregular ad-hoc type jobs can be completed whenever required, without having to schedule availability in the maintenance shop.

The Pow’R-Riser jack also has a lower total cost of ownership. Simpler and cheaper to maintain than an installed system, maintenance costs for your lifting equipment will also fall. The Pow’R-Riser family is also less susceptible to inclement weather and debris, providing another significant advantage over ‘fixed’ lifting systems. In the unlikely event that a Pow’R-Riser jack does fail, you can quickly and easily swap it out – unlike the traditional in-ground lifting systems many rail operators rely on.

Extensive accessory options

The Pow’R-Riser jacks have a range of accessories to extend functionality according to the specifics of your rolling stock maintenance project. Locking U-rings provide additional safety protections when working on railcars that have been lifted. And a range of extenders can be used to increase lifting range by as much as 11 inches as required. A swivel load cap should be used when the amount of misalignment between the standard load cap and the lifting point is too large.

Regulatory standards compliant

Safety and compliance are crucial to the design of the Pow’R-Riser family. Each jack is fully certified to ASME / ANSI B30.1:2015 and CE specifications. These certification marks help ensure that equipment adheres to your in-house standards and regulatory obligations when carrying out maintenance tasks.

For added safety, Pow’R-Riser jacks can also be operated remotely using the included 2-button pendant. Your rolling stock maintenance operatives can raise and lower assets from 20 feet away – far from any risk of crushing or other injury during lifting operations.

Choice of power options

For ultimate portability, choose an air-powered, pneumatic jack, combined with a portable industrial air compressor. This fully-portable option means you can use Pow’R-Riser jacks almost any time, any place.

And if your business must meet strict carbon reduction targets, the electric pumps offer the exact same lifting capabilities – but powered by electricity. From 60 to 100 tons and beyond, there is a jack for every application.

Railcar or railwagon maintenance can be difficult, but it doesn’t have to be if you equip yourself with the right equipment. To learn more about the Enerpac Pow-R Riser portable family of jacks, check out the full range here.

I don’t commonly comment but I gotta admit thanks for the post on this one : D.