What Is a Line Stop Actuator and How Does It Work?

August 16, 2021

0

What is a Line Stop Actuator?

A line stop actuator plays an important part in the hot tapping procedure – a process used in industries such as oil & gas, petrochemicals, utilities, and power generation. Hot tapping allows tees, flanges, and valves to be added to a section of piping, without interruption to the flow of the product.

What a Line Stop Actuator does

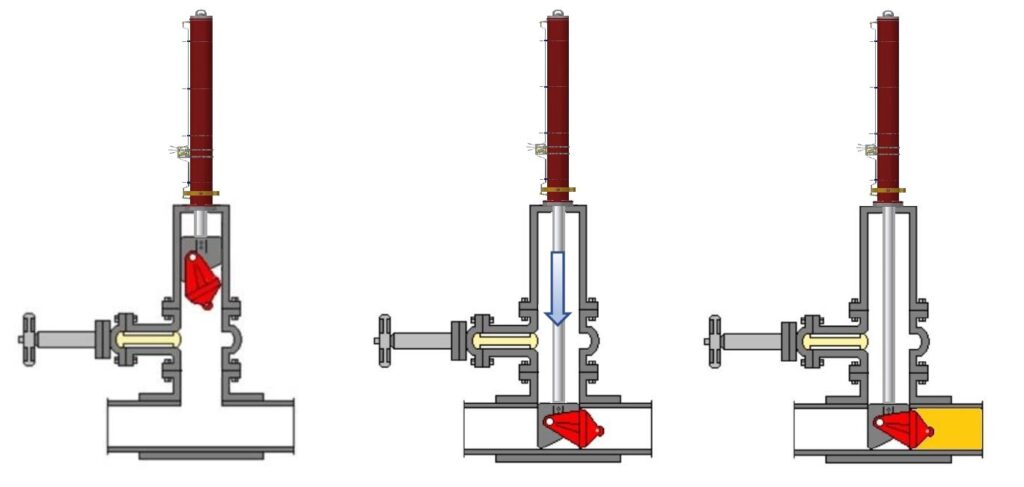

A line stop actuator inserts a folding head into the pipeline to act as a plug. They are typically used on each side of the section where work needs to be carried out.

Doing this allows a temporary bypass to be added, enabling the product to continue flowing through the pipeline. But before this can happen, a hot tapping machine is used to cut into the pipe section and remove the ‘coupon’ (the cut section of the pipe). The attached sandwich valve is then closed, and the line stop actuator can be bolted onto it.

How a Line Stop Actuator works

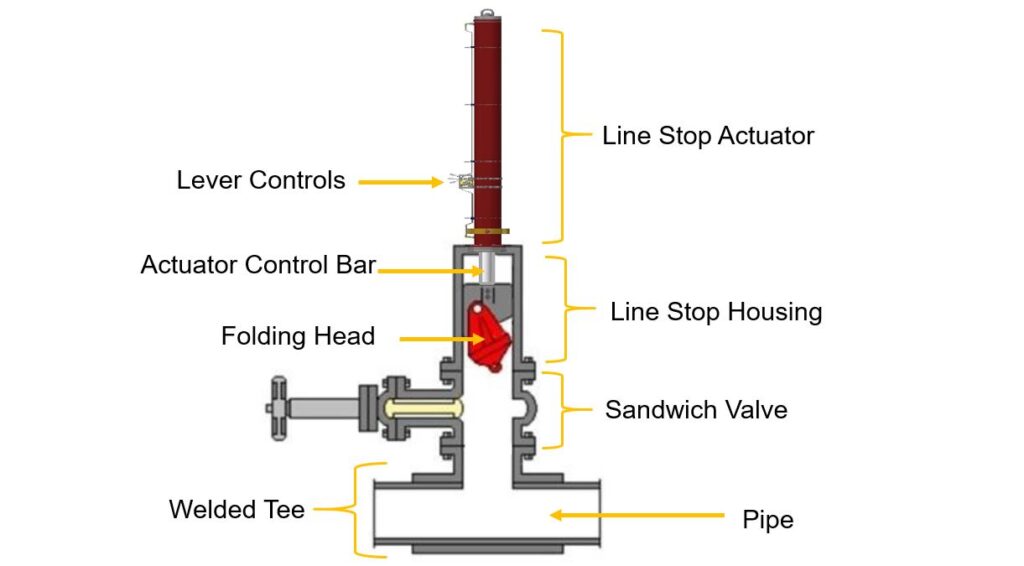

A line-stopping actuator is a sealed unit containing a control bar with a folding head attached. The actuator is fixed to a housing, which in turn is fixed to a sandwich valve that opens to allow the control bar and folding head to enter the pipe.

Hydraulic pressure is supplied to the actuator, causing the control bar to advance until the folding head reaches the bottom wall of the pipe. It then rotates 90 degrees to plug the supply.

The hydraulic controls are operated using levers within a control module on the side of the actuator’s exterior casing. The operator uses these to either extend or retract the control bar. Included on the control bar are markings to track its progress as it moves within the actuator. These are clearly visible through a viewing window built into the actuator casing.

The control bar also works with a feature to provide a secure mechanical lock – providing the reassurance that the plug will not move, despite the high pressures normally present in many pipelines.

Safety Considerations

Many pipe sections contain highly toxic liquids and gases which means the risk of a failed line stop operation can be extremely dangerous.

So, what are the features and characteristics that minimize risk?

Durable materials

As with all hot tapping equipment, any line plugging products should be durable enough to withstand corrosive materials, extreme temperatures, and high pressures. That’s why hard chromium is normally used on the exterior of the control bar. Also of importance is the durability of any seals used – not only on the folding head, but also within the actuator.

Important: Before choosing a line stop actuator you should check it is rated for continuous use at the required temperature.

Alignment and anti-rotation

Through continuous use, some components in a line stop actuator will wear. This can lead to excessive play in the control bar, causing poor alignment of the folding head within the pipe.

However, the new Enerpac LSA-Series actuators tackle this problem head-on using a unique anti-rotation feature. This new method differs from the industry standard ‘slot and key method’ – which over time creates unwanted movement in the system due to fatigue. Choosing a line stop actuator with the new feature will minimize the risk of deployment issues and sealing failures over the longer term.

Dealing with unexpected spikes or drops in pressure

When there are sudden pressure changes within the pipeline a line stop actuator needs to cope with this. With a well-used, or poor-quality product, there is the very real possibility of the folding head unseating – with potentially catastrophic consequences for those working nearby!

When choosing your line stop product, check to see if there is a failsafe mechanical locking device included within the design. A feature such as this will provide much welcome reassurance and peace of mind, both for the operator and staff working at the plant.

Other equipment needed for hot tapping and line stopping

A line stop actuator is just one of many products needed to carry out a hot tapping operation. Other items include,

- Hot Tapping Machine

- Cutters

- Ladder and platform (attached to the hot tapping machine or line stop actuator).

- Pilot Drill

- Housings

- Folding Head

- Power Pack

- Hydraulic Hoses

- Sandwich Valve

- Skids (For transporting)

- Completion Plugs

Decommissioning Case Study Pack

Learn how portable machine tools solved four tough decommissioning challenges

A different way to isolate pipeline

The hot tapping and line stopping procedure involves many steps and relies on large and heavy equipment and specialized skill and knowledge. But not all modifications to piping require this extensive time, effort, and expense.

One example is during maintenance shutdowns. If a pipe run has already been isolated and the end of the pipe is open, quite often there is still the need to plug the pipe to prevent residual gases escaping. Doing this allows hot work such as welding tees and flanges to be completed safely.

For this kind of job, MITT-Series pipe isolation tools offer a simple solution. You can find out more about these tools in another article here.