How to Cut Rebar Quickly and Safely

October 8, 2020

0

Rebar, also known as reinforcing steel bar, is used to strengthen concrete sections when buildings and other large structures are constructed. It arrives on-site in standardized lengths, which means the task of cutting each piece to the required spec lies with the workmen. Knowing how to cut rebar quickly and safely will help boost your efficiency when on-site.

Rebar can be cut using many different tools. If you are a worker on a construction site your needs will be very different from the average handyman. On a typical project, you may be expected to make dozens or even hundreds of cuts. If this is likely, you should consider investing in a purpose-designed tool that works quickly, safely, and efficiently.

Before we look at rebar cutters, let’s look at the alternatives.

Angle Grinders and Circular Saws

Angle grinders and circular ‘gas saws’ are a popular choice, but there are numerous safety risks to contend with.

- First of all, there’s the sparks, which can ignite materials nearby and cause burns if the skin isn’t fully covered. Smoke and dust is created too, which could lead to respiratory problems.

- Then there’s the potential for grinding or cutting wheels disintegrating and firing debris at you or your colleagues. These risks can be mitigated using the correct PPE. But wearing protective clothing, masks and goggles do not make for comfortable working in a hot climate or cramped spaces.

- Kickbacks are another serious threat to worker safety. This can happen when the angle grinder jams into the material when cutting. The last thing you want is to lose control of the tool – potentially dropping it onto your legs or feet!

The Hacksaw

The humble hacksaw is one option if there is a small number of bars to cut. But any more than a few and the process becomes tiring, time-consuming, and inefficient.

The Reciprocating Saw

A reciprocating saw is another option. As with a hacksaw, you will need a suitable blade for cutting rebar – one with fine, sharp teeth. Being hand-held, recip saws can become tiring to use. There’s also the added problem of vibration too, which for the frequent user can lead to HAVS (Hand Arm Vibration Syndrome).

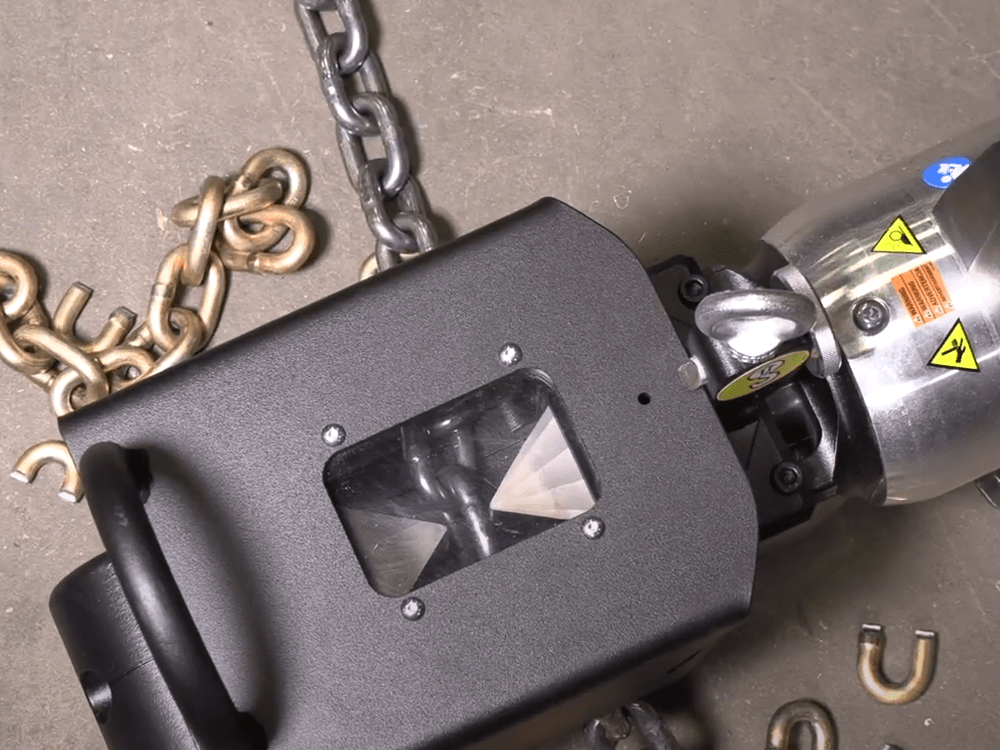

Bar Cutters from Enerpac – Safer and Faster

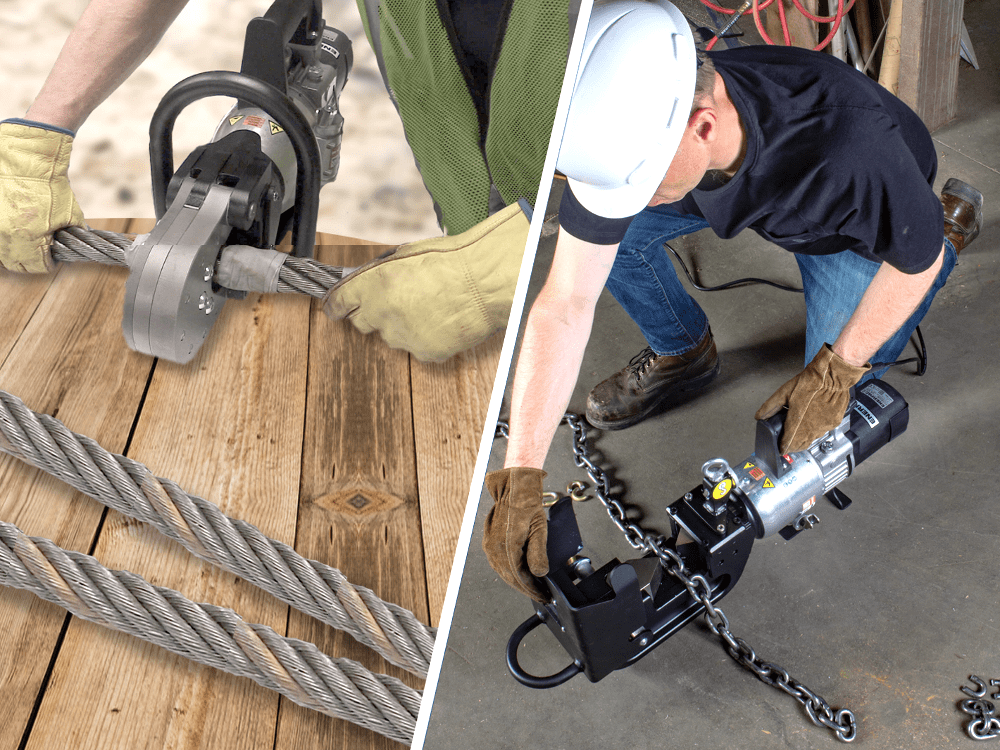

The new Enerpac Bar Cutters cut rebar safely without the threat of exploding wheels or shooting sparks. The rebar is simply placed in a cutting head and a quick, straight cut is then made by a durable blade. Two seconds later, the job is done. There are electric and hydraulic versions to choose from.

The EBE Series Electric Cutters will cut #6 rebar in just 2 seconds. This is faster than a gas saw, which takes 5 seconds, and a cut-off tool that takes 7 seconds.

When using either an Enerpac electric or hydraulic cutter, you will not only save time on each cut, but also by eliminating the need to mitigate risks. Simply plug into the required supply and you’re ready to go!

For larger diameters, the Enerpac EBH series make easy work of cutting up to #14 rebar. These are powered by a separate 10,000 PSI external hydraulic pump. Ideal for heavy-duty and high-volume cutting applications.

Enerpac Electric Bar Cutter and Gas Saw Compared

Watch the speed comparison video showing both types of rebar cutter in action

See the range of bar cutters perfect for cutting rebar on the Enerpac website.