Heavyweights of Hydraulics: Unlocking the Secrets of High-Tonnage Cylinders

May 13, 2024

0

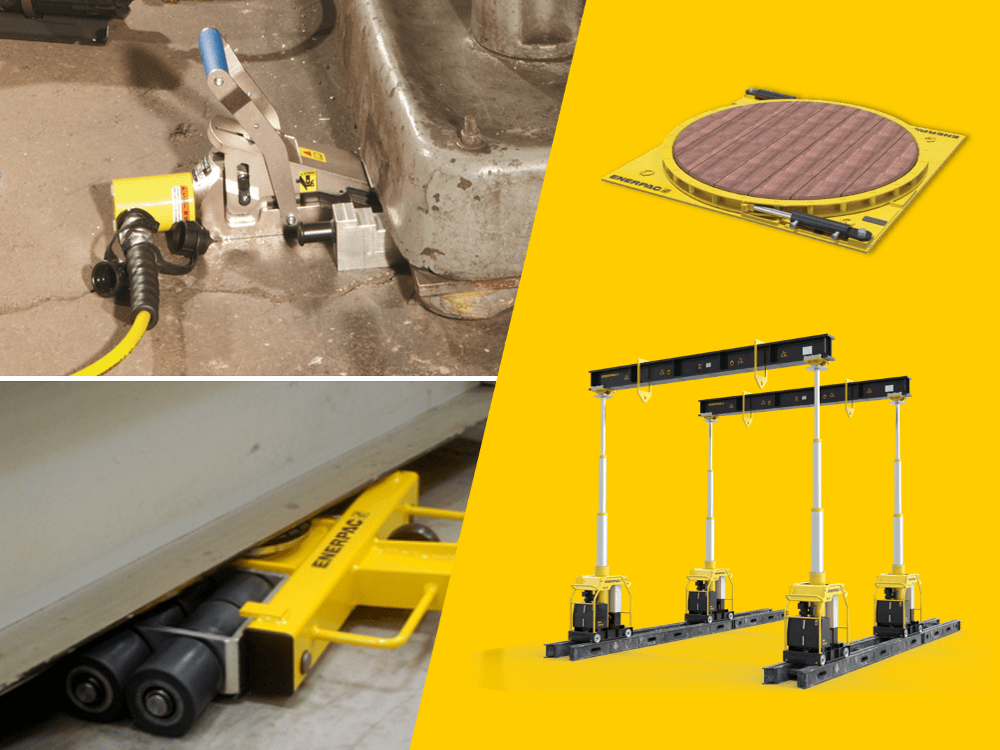

In this article, we’ll explore the essential workings of Enerpac High-Tonnage Cylinders, what sets them apart from other cylinders, and example applications. We also encourage you to look at the interactive image click on the hotspots and share it with any of your contacts who may also be interested.

What Makes a High-Tonnage Cylinder Different?

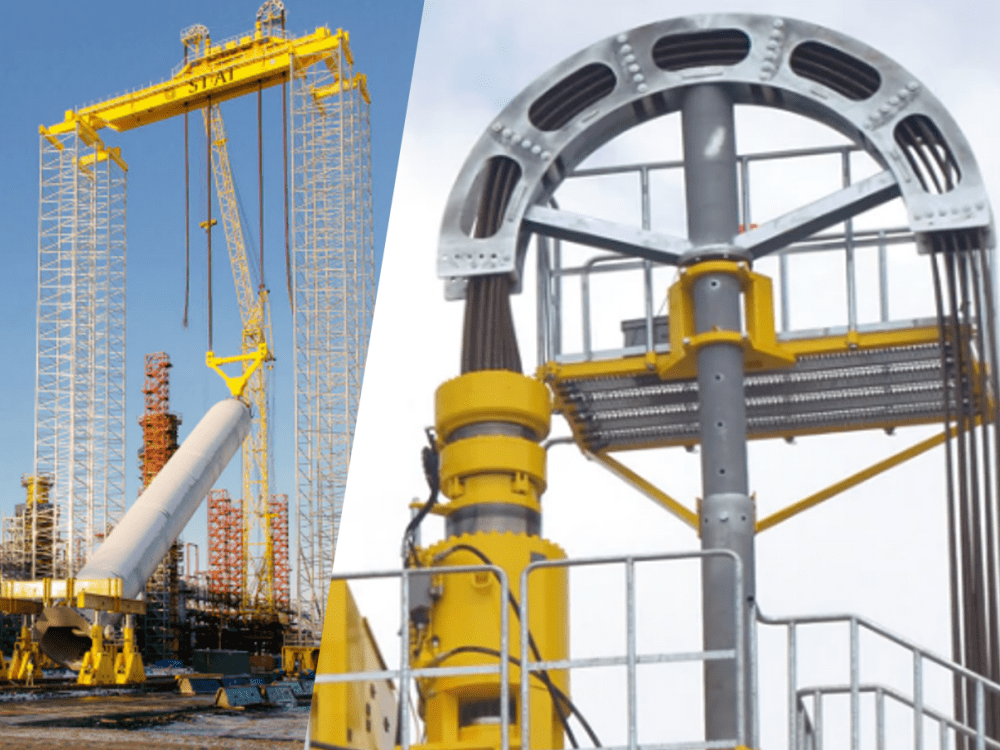

In the world of infrastructure construction, where robustness is non-negotiable, high-tonnage hydraulic cylinders emerge as indispensable assets. For construction engineers tasked with erecting and maintaining bridges and other vital structures, these powerful cylinders are engineered to deliver exceptional safety and durability wherever there’s heavy lifting to be done.

Compared to more ‘general purpose’ hydraulic cylinders, a high-tonnage cylinder is engineered specifically for more demanding projects. First, there’s the obvious difference, which is the greater tonnage capacity, and while some other types also cross over into this area, in general, most high-tonnage models are available in capacities up to 1000 tons.

The type of project they’re used for is typically infrastructure-related, and therefore they may be left outdoors exposed to the weather for some time – which is why they’re finished in a nitrocarburized coating. Not only does this protect from weather conditions, but also from other damage such as knocks, scrapes, scoring, and sideload.

Where are High-Tonnage Cylinders Used?

High-tonnage cylinders are mostly used for construction projects such as bridge assembly and maintenance, for example, when replacing bridge bearings.

Choosing the Right High-Tonnage Cylinders

The key features to consider when selecting cylinders for your project are:

Tonnage Capacity: usually up to 1000 tons

Stroke: up to almost 12” (300 mm)

Return Type: choose between single-acting and double-acting. Single-acting high-tonnage cylinders rely on the weight of the load to return the plunger to its lowest position, whereas double-acting cylinders have an additional port and use hydraulic force which is faster and offers more control.

Locking: Choosing a cylinder with a locknut provides the reassurance of safe mechanical holding – a good choice when the load needs holding for long periods.

External Dimensions: Including collapsed height for fitting into tight spaces, and the base diameter when looking at stability.

Saddle Types: Do you want the ability to replace the saddle, and do you want the option of fitting a tilt saddle to alleviate sideload?

Resistance to Sideload: If you think the load may exert force on the load that is not truly vertical you should look at the manufacturer’s stated resistance to sideload. These can vary between 5% and 10%.

Durability: Nitrocarburization offers maximum durability, but for ad-hoc infrequent use a more budget-friendly equivalent with a baked enamel finish is worthy of consideration.

The Enerpac High-Tonnage Cylinder Range: At-A-Glance

HCG-Series: Single-acting load return. Maximum load capacity 1000 tons.

HCR-Series: Double-acting to provide a faster and more controlled plunger return. Maximum load capacity 1000 tons.

HCL-Series: Includes a lock nut that provides safe mechanical load holding for extended periods. Maximum load capacity 1000 tons.

HCRL-Series: Includes a lock nut and double-acting return, and a tilt saddle provided is standard. Maximum load capacity 300 tons.

LPL-Series: Low profile lock nut hydraulic cylinders, which are low height, single-acting, load return. These also feature a built-in tilt saddle to protect against side load. Maximum load capacity 150 tons.

For more low-height cylinder options, (which are especially useful for bridge bearing replacement where space is tight), consider the CULP and CUSP ‘pancake’ cylinders.

CULP-Series: Low Profile Hydraulic Pancake Cylinders are single-acting, load return, and ultra-flat. They include a stop ring to limit the maximum stroke. (Maximum load capacity 100 tons)

CUSP-Series Low Profile Hydraulic High-Capacity Pancake Cylinders offer greater load capacity, are single-acting, load return and ultra-flat. They include a tilting function to help evenly distribute the load. Maximum load capacity 1000 tons.

Controlled Lifting Pumps

Infrastructure projects requiring high-tonnage cylinders are usually multi-point lifts, which means hydraulic flow to and from each cylinder needs to be synchronized.

This can be achieved using a variety of controlled lifting pumps and accessories. Controlled lifting pumps are a far better alternative than using independently operated pumps, each with their own operator. By controlling the oil flow to each cylinder, the pumps maintain accurate positional control, eliminate manual intervention, increase productivity, and increase the safety of a lift.

There are several different solutions available including:

Split Flow Pumps

Where synchronization accuracy of a maximum of 4% is acceptable, Split Flow Pumps are a safe and economical solution. Flow to each outlet is controlled via the simultaneous operation of valves to provide even flow to each lift point regardless of differences in load. Provided all the cylinders have the same load rating (effective area), the cylinders will move evenly based on this even output flow. Fine-tuning at lift points can be controlled individually.

Evo Synchronous Lifting System

This more sophisticated system controls up to 12 lift points from a single pump unit and uses a PLC (Programmable Logic Controller) to monitor and control each lifting point. Depending on the cylinder capacities used, an impressive accuracy of 0.040 inches (1 mm) between lifting points is achieved.

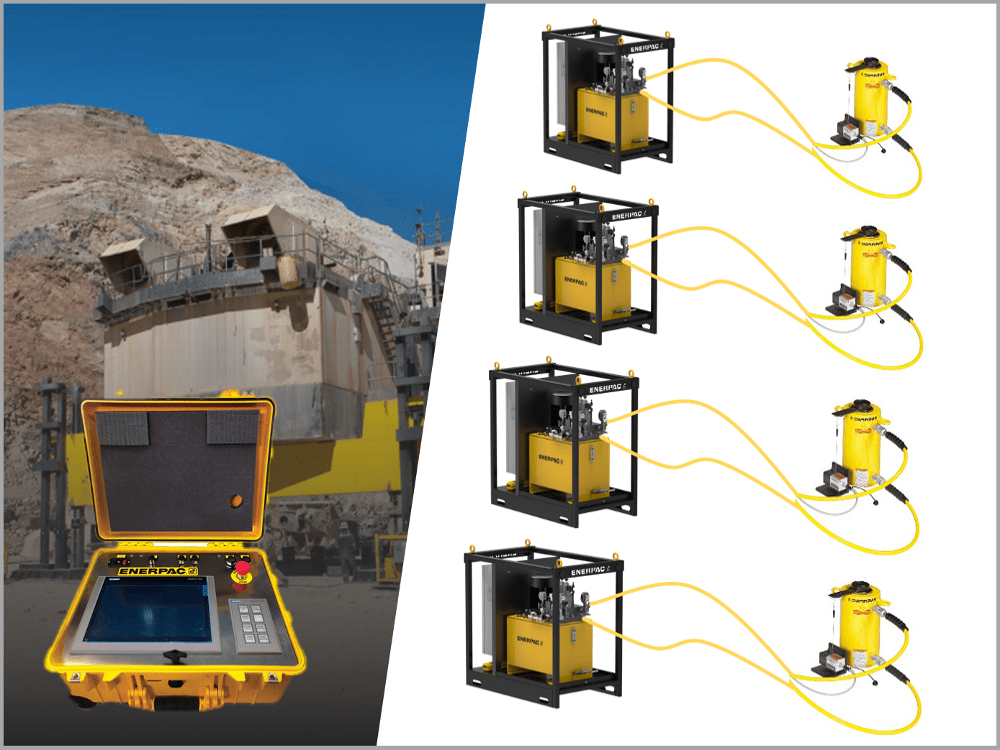

EVOP Pump Per Point System

This arrangement uses a dedicated pump for each lifting point. All are networked together and controlled from a single operator station. The advantage of a pump-per-point system is the combination of higher flow rates with accuracy of 0.040 inch (1,0 mm) between leading and lagging cylinders. The higher flow rate of this system makes it ideal for high-tonnage cylinders, applications using long-stroke cylinders, and repetitive operations.

Conclusion

High-tonnage hydraulic cylinders empower construction teams to tackle monumental tasks with confidence and precision. As infrastructure projects evolve, these hydraulic giants remain steadfast, driving progress and innovation in the dynamic world of construction.

Selecting the right cylinder involves careful consideration of factors like tonnage capacity, stroke length, and return type, each crucial for ensuring optimal performance and safety on-site. The Enerpac High-Tonnage Cylinder Range offers a diverse selection, from single-acting load return to double-acting cylinders with lock nuts, catering to a wide range of project needs with precision and efficiency. Additionally, controlled lifting pumps play a pivotal role in synchronized multi-point lifts, enhancing operational ease and safety.

At Enerpac, our heavy lifting specialists stand ready to assist you in the selection of the right equipment for your infrastructure project.

Contact a Specialist