Post-Tension Concrete Explained: Techniques, Benefits, and Tools

September 10, 2024

0

Post-tension concrete is a mainstay technique of modern engineering and building projects. These post-tensioning methods are popular because:

They offer exponential improvements to the strength of concrete structures.

- Post-tensioned structures, while improving strength, can also reduce concrete and steel material costs.

- By placing concrete under compression, post-tension structures are less likely to crack.

- Thinner, concrete post-tensioned, slabs allow builders to accommodate more floors in a high-rise construction, maximizing return on investment.

- By profiling the strands, designers can control how the load is distributed throughout the structure.

- Stronger post-tensioned concrete structures typically require fewer supports, ideal for projects that require longer spans, including bridges.

When building with post-tensioned concrete, projects consume fewer resources without compromising strength or quality. By using fewer materials, project costs fall, profit margins strengthen and the carbon footprint of the project shrinks – all important goals of any construction program.

How does post-tension concrete work? A brief overview

Post-tension concrete combines the relative merits of concrete and steel to deliver a final product that is much stronger than either used alone. Concrete offers superb strength when under compression. However, when that slab structure is placed under tension, it can be weakened and is prone to cracking.

Rebar

Adding steel reinforcement (rebar), a passive reinforcement system, to the pour offers some tensile strength improvement – but it still has structural capacity limitations. Rebar-reinforced concrete may still be liable to cracking for long, unsupported slabs for instance.

The solution? Post-tension concrete, which is an active reinforcement system. There are two main types of Post Tension Systems; Bonded and Un-bonded. This article focuses primarily on the bonded post-tension method. A post-tension concrete structure will probably contain rebar, typically around the post-tension anchorage areas.

Post-tensioning strands

The main element in the post-tensioned structure is the addition of the post-tensioning strands. These steel strands run through ducts embedded in the structure. The strands are secured at one end of the structure, with an anchorage device, and then passed out of the opposite edge of the structure. The installation process is generally relatively straightforward.

Pouring the concrete

Pouring then continues as normal, with special care taken not to allow concrete to leak inside the tendon duct (doing so risks creating rust and other long-term structural problems).

Stressing the strands

Once the concrete has sufficiently cured, the exposed strands are stressed with specialist tools to create internal forces that place the concrete in compression to counteract external loads. The exposed end of the strand, typically referred to as the “LIVE” end, is secured using an anchorage device embedded in the structure to maintain the desired tension for the lifespan of the structure. In many cases, after final tensioning, the duct may be filled with a cementitious filler to further protect the strands from corrosion and to bond the tendons to the ducting.

Adding post-tensioning in this way allows for the creation of a far stronger concrete structure with superior wind and seismic resistance qualities.

Where is post-tension concrete used?

Stronger, longer, thinner and more crack-resistant than traditional structures – there are many places where post tension concrete is used, including:

- Bridges – Long, load-bearing bridge spans are perfect for crossing gaps at height.

- Skyscrapers – By using post tension slabs to reduce deflections and cracking, allowing for thinner slabs and larger spans between supporting columns.

- Parking structures – Again, large spans between columns are essential for maximizing available space for car parking.

- Industrial floors – Fewer floor joints and less cracking make post-tension concrete an extremely durable surface for factories and other industrial structures.

- Sports stadiums – Heavy load-bearing capabilities and cantilevered architecture require high-tensile concrete solutions.

Indeed, any application where there must be long, unsupported stretches of load-bearing concrete is a candidate for post-tension slabs.

What equipment do you need for post-tensioning concrete?

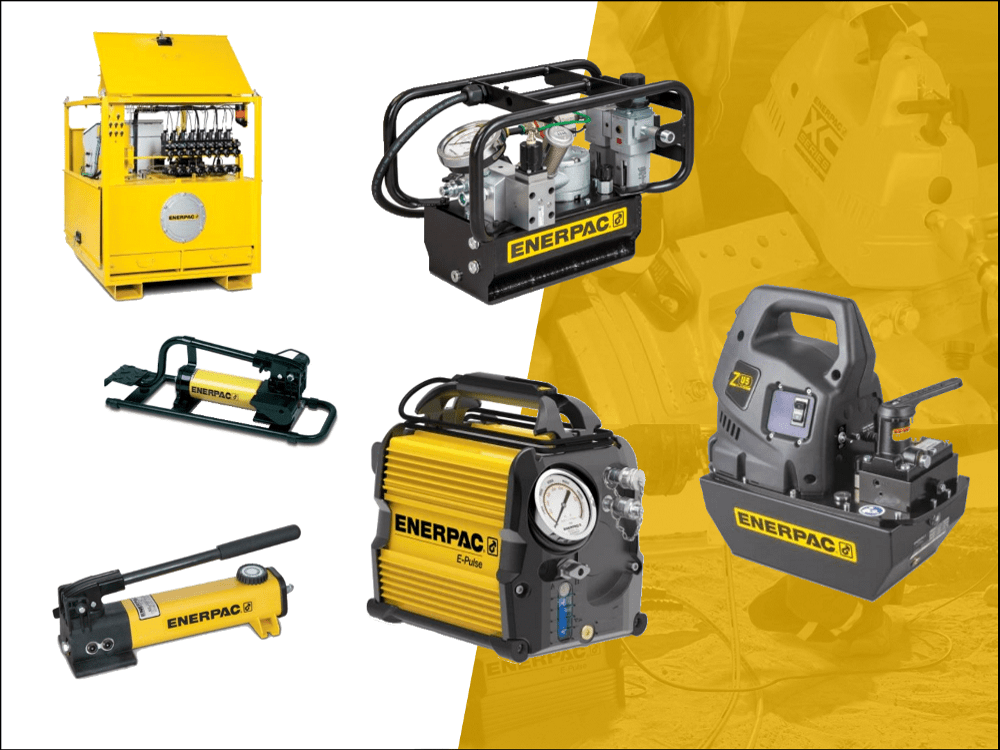

The steel strands running through post tension concrete are typically placed under 33,000 pounds-force (lbf) tension. To support this high level of tension, tendons are made from very strong, 7-wire, spiral-wound steel. Delivering a precise level of tension requires specialist tools, specifically stressing jacks and tensioning pumps.

Introducing the Enerpac ZU5 Post-Tensioning Pump

The Enerpac ZU5 Pump series is particularly popular with post-tension slab contractors because of its increased flow rates. The ZU5 family boosts productivity by stressing tendons 30% faster than traditional hydraulic pumps. There are two ZU5 pump variants available according to the specific needs of your project:

The ZU5708RB-P tensioning pump for single-acting mono-strand stressing jacks. This is ideal when working on slab-on-grade projects.

The ZU5908PB-P tensioning pump for double-acting mono-strand stressing jacks. This is ideal when working with elevated slabs.

Extremely efficient and effective, both pumps improve productivity, allowing your team to stress more tendons each day, reducing labor and associated costs.

You can find the full specifications of Enerpac ZU5 Post Tensioning Pumps here. Single-acting Double-acting

Anything else?

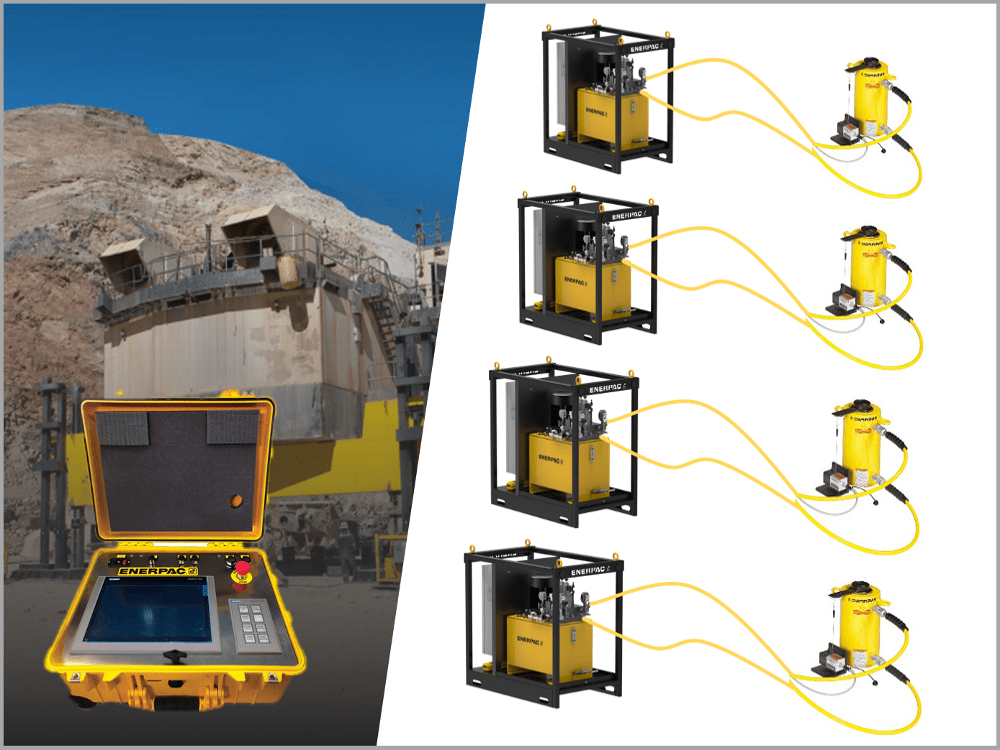

Pouring post-tension concrete in place may need additional equipment, particularly where the project calls for structures to be raised above ground level. If heavy lifting is required, equipment like strand jacks or synchronous hoist systems may be an excellent addition to your on-site assets.

To discuss a project or to obtain a quote please get in touch.