How to Bleed Air from a Hydraulic Cylinder

July 26, 2022

0

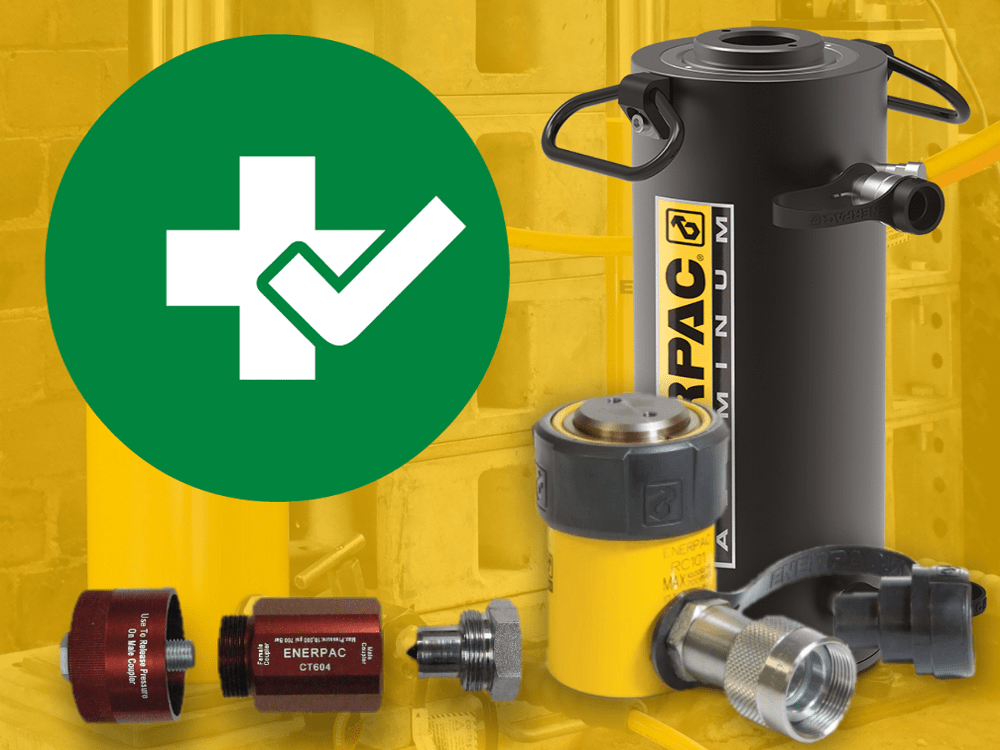

Knowing how to bleed air from a hydraulic cylinder and the connected system is vital to ensure correct performance. In our video below, we show you how to bleed a single-acting hydraulic cylinder, and also how to bleed a double-acting hydraulic cylinder. The process explained by a trainer from the Enerpac Academy shows a quick and safe method to purge air from the system.

How to Tell if Air is Present in a Hydraulic System

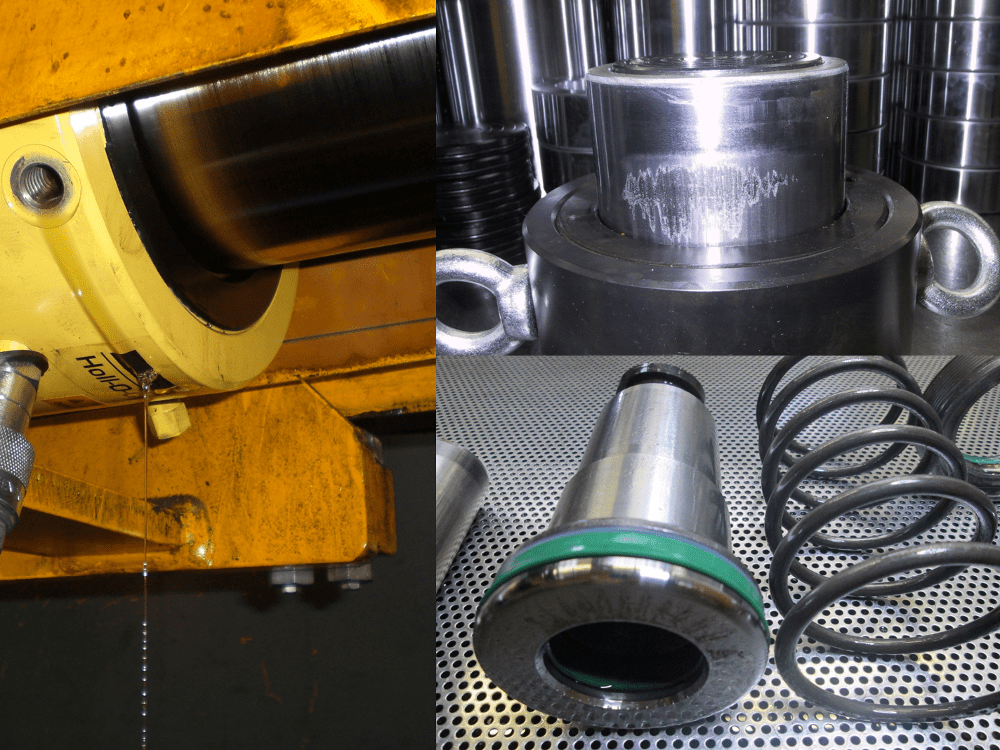

If the plunger has a spongy feel or advances with a jerky or pulsating motion, this is a clear sign that air is trapped in the hydraulic system. These unwanted movements are caused by the compressible nature of the trapped air, so it should be purged from the system. Over the long term, air can result in oxidation, increased viscosity, sludge, depleted additives, and increased acidity. The air trapped inside the system can lead to cavitation, which is when vapor bubbles are produced due to a rapid change in fluid pressure. These bubbles then collapse and cause small vibrations and shock waves. If this happens repeatedly, metal parts in the system may be damaged

How Air Gets into a Hydraulic System

Aeration of hydraulic oil can occur through air getting into the system through seals and fittings, or during maintenance. It’s also worth knowing that hydraulic fluid naturally contains air. Dissolved air in hydraulic oil is not problematic, but if cavitation occurs the resulting bubbles will be an issue.

How to Bleed Air from a Hydraulic Cylinder – Step-by-Step Process

- Attach your hose to the cylinder – if empty of oil it will take longer to bleed. If your cylinder is double acting, attach hoses to both couplers and use a double-acting pump.

- Next, place the hydraulic cylinder below the pump – either by elevating the pump or lowering the cylinder. Try to position the cylinder with the ports facing up. This will force the air up to the pump.

- Make sure the hydraulic pump reservoir is vented. Advance and retract the cylinder with little or no pressure. This will show you if the cylinder is working correctly.

- Repeat the advance and retract cycles several times to watch for a smooth operation. If you see any evidence of jerky, spongy or pulsating motions you will know there is still air within the system.

- Repeat the cycle until the plunger operation is smooth and consistent.

For more info contact a regional Enerpac representative

If you require hydraulic oil, cylinders, or pumps you will find a wide selection to choose from on our website.