Hot Bolting and Single Stud Replacement

September 14, 2021

0

What is Hot Bolting?

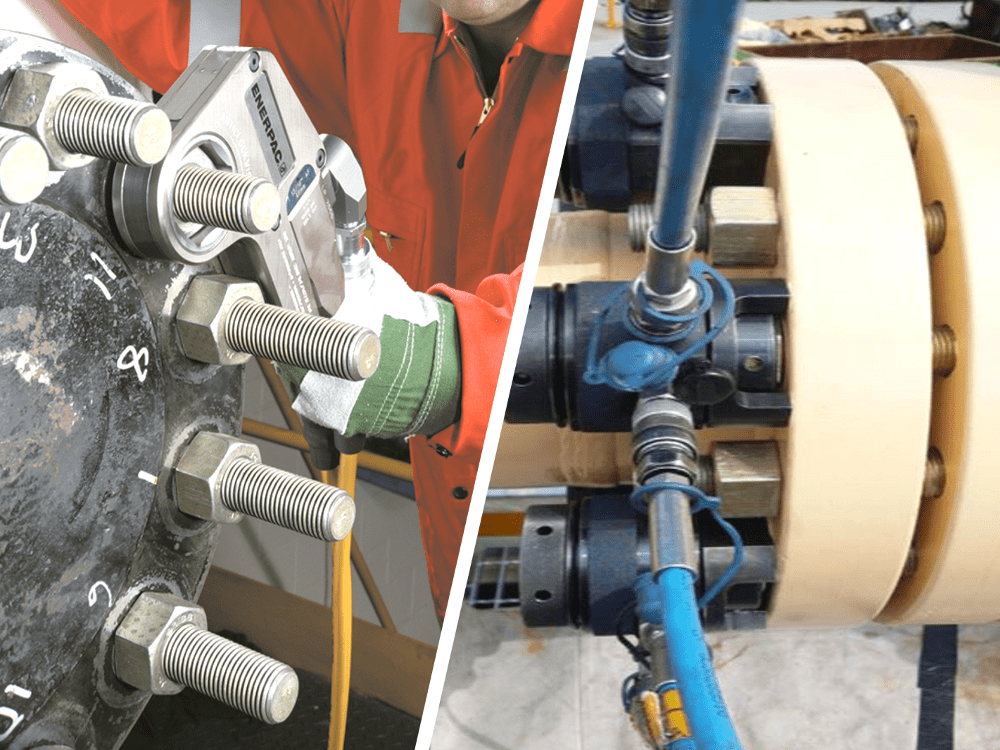

Hot bolting is a term used to describe the technique of re-tightening or replacing flange connection bolts when a pipe is live – (full of liquid or gas).

There is some confusion around the phrase as there are several similar and related terms often used (sometimes incorrectly). These include hot torquing, live tightening, single stud replacement, live bolting, and retorquing.

While hot bolting is the more commonly used term, this can be misleading as the procedure is not always carried out at a hot temperature. Furthermore, each of the other terms mentioned above can relate to a different process – with a distinct purpose and individual risks.

Hot Bolting: The ASME Definition

For an official definition, refer to appendix B of the standard PCC-1_2019, ASME (The American Society of Mechanical Engineers). In this document hot bolting is defined as

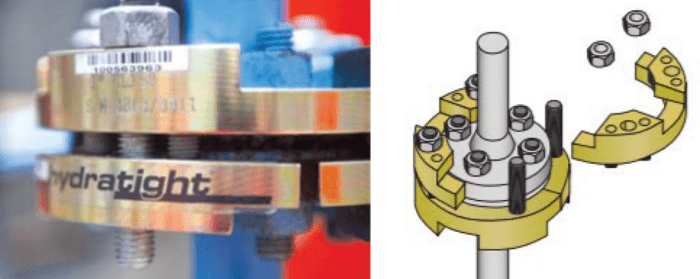

“The sequential removal and replacement of bolts on flanged joints while the unit is under reduced operating pressure. The procedure generally consists of removing one bolt at a time in a flange, relubricating it, reinstalling it (or a new bolt), and retightening it to a specified torque. Hot bolting can be performed while the unit is online or once the unit is depressurized”.

Given the dangers involved, it is vital to understand exactly what needs to be carried out. If the intention is to replace individual bolts (not just to retighten), using the more accurate term single stud replacement is recommended.

What is Single Stud Replacement?

Single stud replacement is the procedure defined in the ASME description above. It is done while the pipeline is still live, often just before a maintenance shutdown. Doing this while the pipe is still active allows critical pipework connections to be disassembled quicker during the outage. The benefits are significant, with an estimated 30% increase in turnaround efficiency.

Benefits of Hot Bolting (Single Stud Replacement)

- Allows damaged or corroded bolts to be replaced.

- Prevents unplanned shutdown.

- Increases safety.

- Helps towards improved joint integrity.

- Reduces duration of shutdown.

- Limits the number of ‘containment breaks’

- Increases efficiency.

- Replaces ‘old for new’ bolts before shutdown.

- Reduces costs.

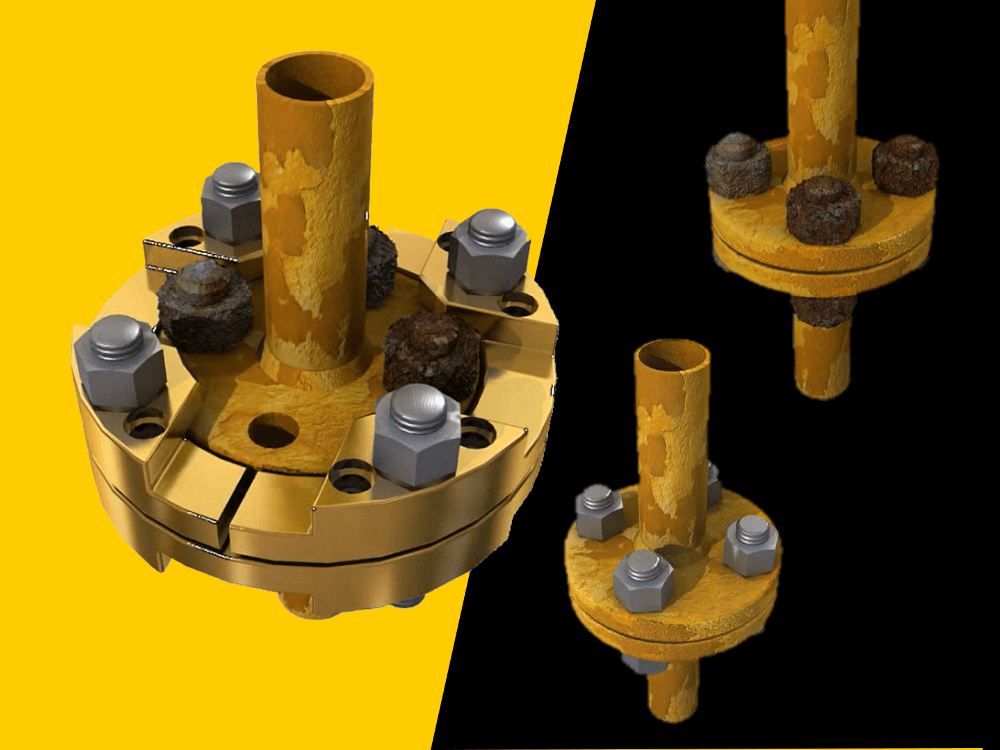

Safe hot bolting on old flange connections can reduce these concerns:

- Unknown remaining bolt tension after a long time in operation.

- Unknown conditions of the bolts.

- Unknown conditions of the gasket.

- Unknown how the gasket will act under increased or decreased load.

- Failure of bolts during hot bolting operation on the adjacent bolt.

- Unknown external loading.

- Unknown how much force is needed to remove old, rusted bolts.

- Changes in operating parameters like flow, temperature, or pressure.

The Risks

In 1992 an explosion and fire caused several fatalities and destroyed much of an oil refinery in Sodegaura, Japan. During the explosion, debris weighing 1800 kg (4000 lbs) was ejected over 200m (600ft). One of the causes was identified as incomplete hot torquing (live tightening). This was due to a lack of competency of the staff, and an inadequate Job Safety Analysis.

So, you will see that hot bolting is regarded as a high-risk activity. Therefore, it should only be done by experienced and qualified personnel – and only after a thorough risk assessment and job safety analysis has been done.

More Information and Resources

Applicable Standards

ASME PCC-1 Appendix B: This covers definitions of hot bolting and related terms.

ASME PCC-2 Article 3:11: The most complete guide on single stud replacement.

Blog Article: Bolt Tightening Sequence: Why It Matters

Hot Bolting Services: Learn more about hot bolting services on the Hydratight website.