7 Ways the Enerpac LGH3100 Hydraulic Puller Transforms Heavy Industry Maintenance

February 17, 2025

0

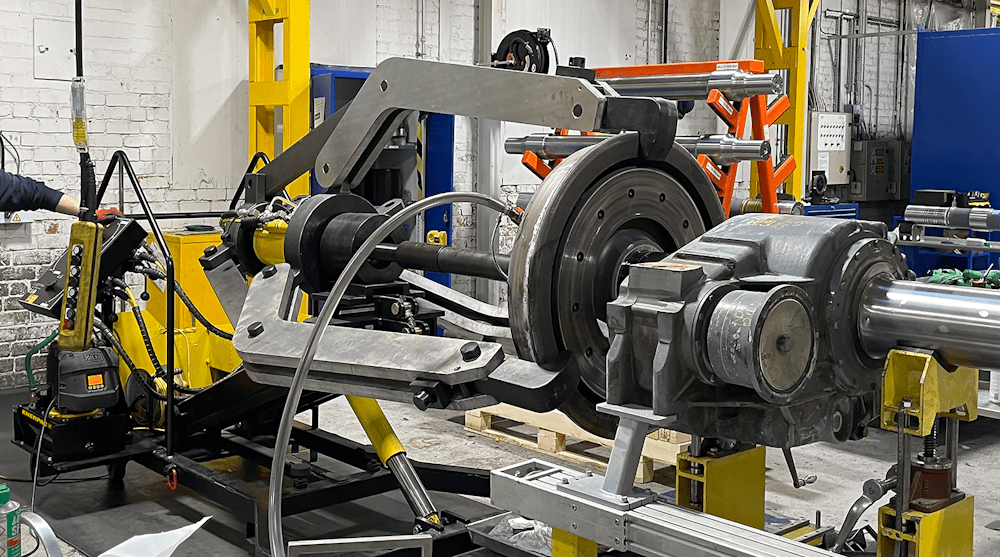

In the demanding worlds of railway and mining maintenance, efficiency and safety are paramount. The new Enerpac LGH3100 Hydraulic Lock-Grip Puller can revolutionize how maintenance teams handle heavy-duty components across these industries. Here’s how this innovative 100-ton puller can transform maintenance operations:

1. Single-Operator Efficiency Revolutionizes Workflow

Gone are the days of requiring multiple technicians for component removal. Whether you’re working on railway wheelsets or mining conveyor systems, the LGH3100’s synchronized grip jaw system and intuitive operator station allow just one or two technicians to handle complex pulling operations. This not only reduces labor costs but also streamlines maintenance schedules, enabling more efficient use of your workforce.

2. Enhanced Safety Through Controlled Force Application

Traditional removal methods often involved dangerous practices like torch cutting and hammering, putting both workers and equipment at risk. The LGH3100 eliminates these hazards by providing up to 100 tons of controlled hydraulic force. Its synchronized locking jaws ensure components are captured and held securely throughout the removal process, whether you’re maintaining mining crusher equipment or locomotive transmissions.

3. Precision That Preserves Component Integrity

When dealing with expensive components like mining vehicle transmissions or railway wheelsets, damage during removal can be costly. The LGH3100’s smooth action and precise force control prevent the typical damage caused by off-center pulling or excessive force application. This precision helps maintain the integrity of both the removed components and the mounting surfaces, crucial for both mining and railway applications.

4. Unmatched Versatility in Component Access

The puller’s innovative design allows for both 3-jaw and 2-jaw configurations, making it exceptionally versatile across industries. Whether accessing tightly confined spaces in mining conveyor systems or working with larger components like crusher assemblies and locomotive wheels, maintenance teams can quickly adapt the tool to meet their needs without purchasing additional equipment. This flexibility is particularly valuable when working with various types of heavy industrial components.

5. Ergonomic Design Reduces Maintenance Time

The LGH3100’s ergonomic features significantly reduce physical strain and speed up maintenance procedures. Its hydraulic scissor lift provides effortless height adjustment from 27.5 to 66.1 inches (699mm to 1679mm), eliminating the need for additional lifting equipment. The mobile cart design with industrial castor wheels ensures easy positioning around mining sites and railway facilities, reducing setup time and improving workflow efficiency.

6. Control System Enhances Precision

The three-lever control system paired with a remote pendant provides unprecedented control over the pulling operation. Operators can precisely manage jaw positioning, pulling force, and height adjustment from a safe distance. This level of control is crucial when working with components in both mining equipment and rolling stock, ensuring consistent and damage-free removal every time.

7. Built for Heavy-Duty Industrial Applications

Engineered specifically for demanding industrial environments, the LGH3100 is built to excel in both mining and railway facilities. Its robust construction and reliable ZE3-Series electric two-stage pump ensure consistent performance even under the most challenging conditions. The tool’s 100-ton capacity handles everything from routine maintenance to the most stubborn, corroded components, whether you’re working on massive mining equipment or railway rolling stock.

Conclusion

The Enerpac LGH3100 Hydraulic Lock-Grip Puller represents a significant advancement in heavy industry maintenance technology. By combining power, precision, and safety in a user-friendly package, it can help mining operations and railway facilities improve efficiency, reduce costs, and maintain higher safety standards. For maintenance operations looking to modernize their approach to component removal across heavy industries, the LGH3100 offers a transformative solution that pays dividends in both time and cost savings.