Pipe Diameters: A Simple Guide To Sizing And Schedules

October 31, 2019

0

If you are new to the world of in-situ machining one of the essential things you must learn is how pipe sizing works.

There’s not a huge amount to remember, but you do need to familiarize yourself with the terminology and the underlying methods behind how pipes are classified by manufacturers in the oil and gas sector.

What is the NPS of a pipe?

So what exactly does NPS mean? Is it the inside diameter, the outside diameter? or the wall thickness?

The answer is none of the above.

‘NPS’ is an abbreviation of Nominal Pipe Size, which is a term used as a guideline number defining the diameter of the pipe.

What is pipe NB (Nominal Bore)?

This is just the same as NPS. ( It is a common way of describing pipe sizes used in the USA).

What is DN (Diameter Nominal)?

This is the international and European metric method used to describe NPS (or NB).

DN pipe sizes numbers are therefore different to NPS. For example the metric equivalent of an NPS 6 pipe (6”) is DN 150. (To convert from NPS 6 to DIN simply multiply the 6 x 25=150. (150mm)

What is a Pipe Schedule?

Pipe schedule (SCH) is how the wall thickness of a pipe is described. It is not an actual measurement, but a guide number based on a wall thickness formula.

Two pipes the same diameter may have different schedules, which means they have a different wall thickness. So somebody specifying a pipe for a high pressure application will select a bigger number which represents a bigger schedule (wall thickness).

Additionally, in the case of stainless steel, piping schedules are specified with a letter ‘s’ as a suffix after the number. An example to illustrate is an NPS 14 pipe with a schedule of 40s shown in the table below.

The reason stainless steel is schedules are treated in this way is due to their extra strength. Less wall thickness is required to withstand the same pressure as compared with other steels.

| NPS Nominal Pipe Size | 40 Schedule | 40s Schedule |

| 14 | 0.438″ wall thickness | 0.375″ wall thickness |

The list of pipe schedules used today are as follows; 5, 5S, 10, 10S, 20, 30, 40, 40S, 60, 80, 80S, 100, 120, 140, 160, STD, XS AND XXS.

Just when you thought you were beginning to understand pipe sizing unfortunately there’s an added complexity to be aware of:

Different sizes of pipes are manufactured in different ways and this has affected how pipe sizing works.

What this means is that sizes (NPS) ⅛″ up to 12″ have an outside diameter that is greater than its nominal pipe size, whereas pipe sizes 14″ and above have an outside diameter equal to its nominal pipe size. The diagram below illustrates the point.

Pipe Sizing Charts

If you Google ‘Pipe Size Charts’, you’ll find plenty of pipe manufacturers who offer these to download from their website. We’ve also created our own for you to download Pdf documents using the links below. Depending on your location choose between inches or mm and download for free.

Download NPS (Inches) Pipe Size Chart – (US Letter Size Pdf)

Download DN (mm) Pipe Size Chart – (A4 Size Pdf)

What tools are available for managing pipe flanges?

There are many different tools available for tasks such as flange alignment, flange separation, and flange facers for machining flange surfaces to ASME specifications.

What equipment is available to machine pipe?

If you are looking to cut, bevel, or tap into metal pipes there is a wide range of portable machine tools available.

Pipe Cutting and Beveling

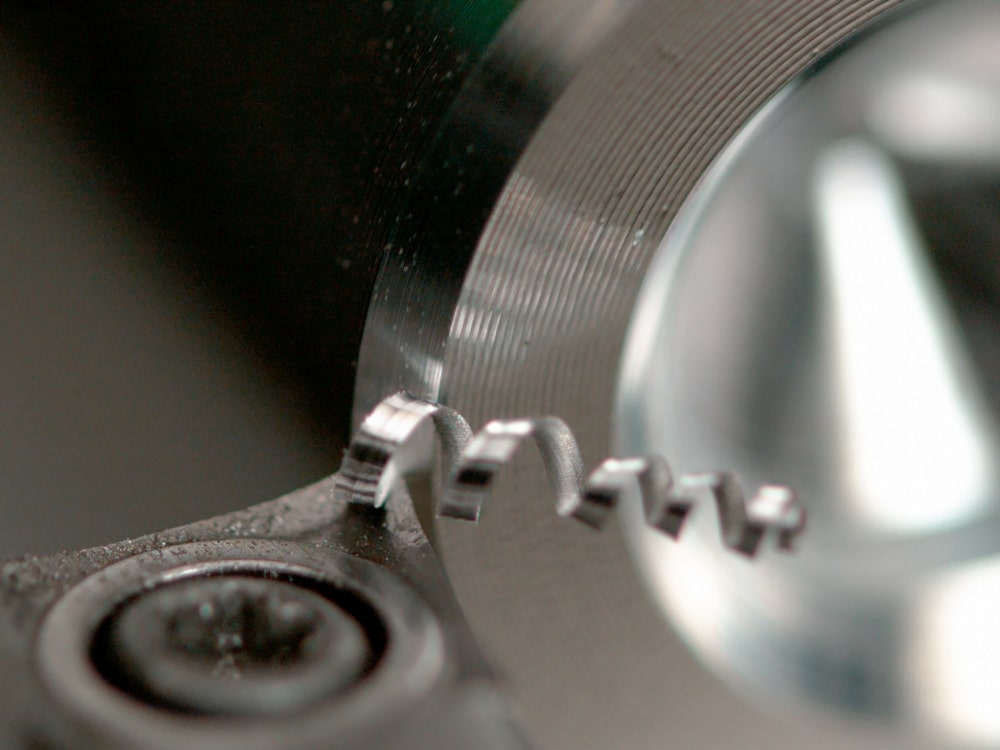

For cutting and bevelling pipelines at on-site at locations such as offshore platforms, petrochemical plant and power stations the tried and test solution is to use a clamshell cutter (also known as a split from cutter). These are available in many sizes with some even capable of machining diameters as large as 180”!

Hot Tapping

When maintenance work on an active pipeline is needed a hot tapping machine can be used. This could be to repair a section of pipeline, or when a new branch needs to be added. The benefit of a hot tapping machine is that the work can be carried out without major disruption to the flow of product through the pipeline.

Milling Pipe Seam Welds

On occasions where subsea pipe connectors are to be used for attaching a new pipe run, it may be necessary to remove seam welds from the pipe to ensure a good fit. This operation is carried out using a portable milling rail attached to the pipe with a chain clamp.

Decommissioning Pipelines

For decommissioning pipelines, a subsea diamond wire saw can be used. These can be either lowered from deck above the surface or hooked up to a remotely operated vehicle (ROV).

Get in touch Contact Us