How to Choose a Hydraulic Torque Wrench

October 7, 2020

0

The hydraulic torque wrench has come on a long way since they were first introduced in the early 1960s. Advancements in technology have created a myriad of features and options to decipher – making it much harder to have confidence in your final selection.

If you’re a seasoned bolting specialist, then you’ll know the must-have features needed to complete your particular bolting projects like a pro.

But if you’re new to bolting, or if you’re buying a torque wrench on behalf of a colleague it’s time to do your homework. Check out the key considerations we’ve listed below.

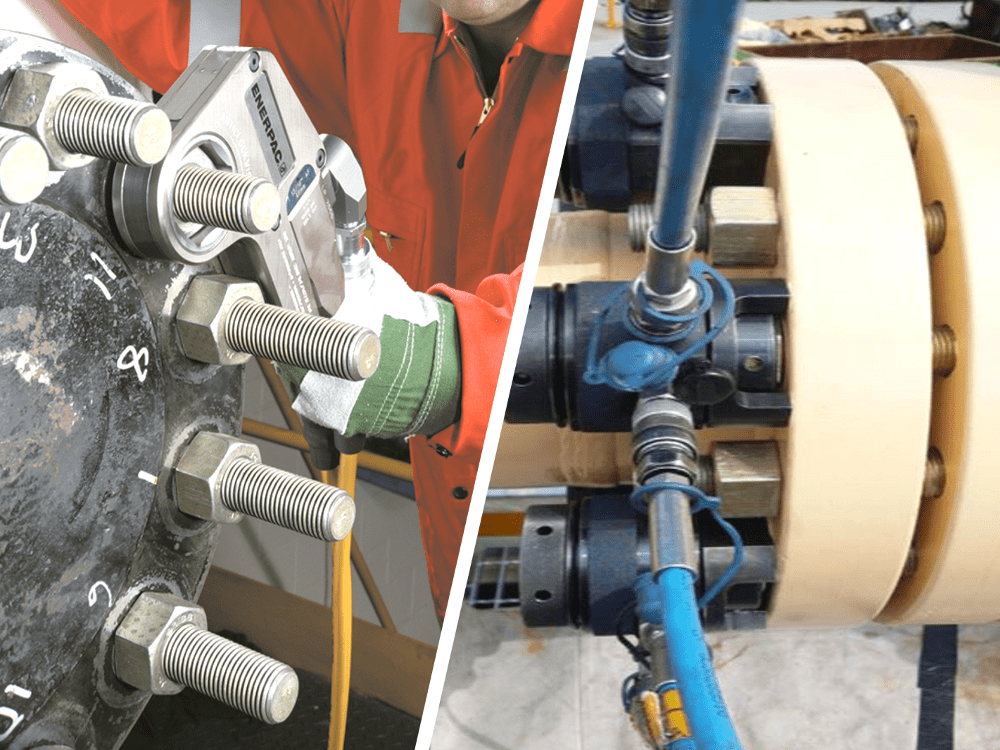

Square Drive or Low Profile

A square drive hydraulic torque wrench shares the same principle as the torque wrench you might have in your garage. It works with different sized sockets to fit the nut to be tightened or loosened.

A low-profile torque wrench uses interchangeable cassettes (sometimes referred to as ‘links’). This type of tool is commonly used in the oil and gas industry where clearance around the nut is often restricted.

Heavy user or an occasional user

Most hydraulic torque wrenches from reputable manufacturers are robust, reliable, and fit for purpose. But heavy users often opt for higher-end products, such as the Enerpac S Series (square drive) and W Series (low profile). At this level, expect hassle-free ownership, superior quality, and extra features, such as quick-change cassettes.

Versatility and multi-purpose

If you want fewer tools that serve a wide range of applications, then consider multi-purpose tools. Good examples are the RSL Series and the aluminum-bodied HMT Series from Enerpac. Both include modules for square-drive and low-profile applications.

Size and Torque Output

Will it be powerful enough and the right size to do the job? Each hydraulic torque wrench works with many different cassettes or sockets. But there are many different drive heads to choose from. Each has a different maximum torque output and is designed to cover a certain range of hex sizes. You should understand the minimum and maximum sizes you want to cover. Then check specifications on the manufacturer’s website.

How much do I need to invest in a hydraulic torque wrench?

Opinions vary. It’s really down to whether you’re thinking short term or long term.

If weighing up the total cost of ownership over the long term is your preferred approach, then build maintenance into your costings. Higher quality products require much less maintenance, but you will invest a little more at the outset.

If you don’t intend to use the tools frequently, then mid-market products provide a good enough solution. This category includes interchangeable and modular designs – enabling you to cover a wide range of applications with fewer tools. Examples adopting this approach include the Enerpac RSL Series. These offer a cost-effective change from low profile to square drive, or vice versa, using the same drive unit.

Are you looking to upgrade your torque tools but want to continue using your existing cassettes and drive units? Select a torque wrench portfolio, such as the Enerpac HMT Series. These use drive heads and cassettes that are interchangeable with the parts from other major manufacturers.

In practice, what this means is if you choose an Enerpac HMT Series drive unit you can use it with cassettes from other main brands. Interchangeability works the other way round too. Buy an Enerpac HLP cassette and this will work with drive units from other main brands.

Convenience, safety, and easy operation

If you’re buying for someone else, make sure you understand what their expectations are for how the tools operate. There’s plenty of features available that offer improved usability and safety. There’s safety handles, swivel hoses, tether points, no-drop features, and quick-change cassettes. Each of these can make a huge difference when working in challenging conditions, such as offshore, or up high on a wind turbine tower.

Steel or Aluminium?

This is rarely a major factor when people choose a hydraulic torque wrench. A torque wrench with a body constructed in either material will be robust enough for most applications. However, it’s worth knowing that steel is stronger but marginally heavier than aluminum. Steel torque wrenches also tend to be smaller – allowing them to fit more applications.

Cassette Choice

If you select a low-profile type of torque wrench, you’ll need to choose cassettes to suit various A/F hex sizes (Across/Flats). For each drive head there’s many available to suit both imperial and metric sizes. Note that different ranges of torque wrenches from the same manufacturer often have dedicated cassettes. Don’t assume all are compatible with each other. But as mentioned earlier, the HMT Series is an exception and is compatible with cassettes from the main manufacturers. By default, cassettes for low profile torque wrenches are designed for tight spaces. But there are other more slimline types available. These are perfect for applications where flange nuts are positioned very close together.

Accessories

There’s numerous accessories available for hydraulic torque wrenches. These add additional safety, certainty, convenience, and extend the amount of applications. Examples include torque wrench pumps, sockets, back up spanners, different sized reaction arms, safety handles and reducers.

Summary

You will see that choosing a hydraulic torque wrench requires careful consideration. A recap of the above points is listed below. If you need any guidance, get in touch with your nearest Enerpac distributor.

Key considerations for choosing a hydraulic torque wrench

- Square drive or low profile?

- Versatility and multi-purpose

- Hex sizes and torque output?

- Heavy user or an occasional user?

- Initial cost vs total cost of ownership

- Convenience, safety, and ease of operation

- Steel or Aluminium?

- Cassette Choice

- Accessories